Uncompromising Quality in Best Tray Cables Made in China for the Global Market

In the ever-evolving landscape of electrical wiring, tray cables have emerged as a critical component for various industrial applications, particularly in the global market. According to a recent report by Research and Markets, the global tray cable market is projected to grow at a CAGR of 5.2% between 2021 and 2026, driven by increasing demand for energy-efficient and reliable wiring solutions. As businesses seek to enhance their operational efficiency and infrastructure safety, the importance of uncompromising quality in tray cables manufactured in China cannot be overstated.

Chinese manufacturers are leveraging advanced technology and stringent quality assurance processes to produce cables that not only meet international standards but also cater to the unique requirements of diverse applications such as data centers, power plants, and manufacturing facilities. This blog will delve into the reasons behind the rising prominence of Chinese-made tray cables in the global market, emphasizing their quality, performance, and compliance with regulatory standards.

In the ever-evolving landscape of electrical wiring, tray cables have emerged as a critical component for various industrial applications, particularly in the global market. According to a recent report by Research and Markets, the global tray cable market is projected to grow at a CAGR of 5.2% between 2021 and 2026, driven by increasing demand for energy-efficient and reliable wiring solutions. As businesses seek to enhance their operational efficiency and infrastructure safety, the importance of uncompromising quality in tray cables manufactured in China cannot be overstated.

Chinese manufacturers are leveraging advanced technology and stringent quality assurance processes to produce cables that not only meet international standards but also cater to the unique requirements of diverse applications such as data centers, power plants, and manufacturing facilities. This blog will delve into the reasons behind the rising prominence of Chinese-made tray cables in the global market, emphasizing their quality, performance, and compliance with regulatory standards.

Unmatched Durability: The Key to China's Best Tray Cables

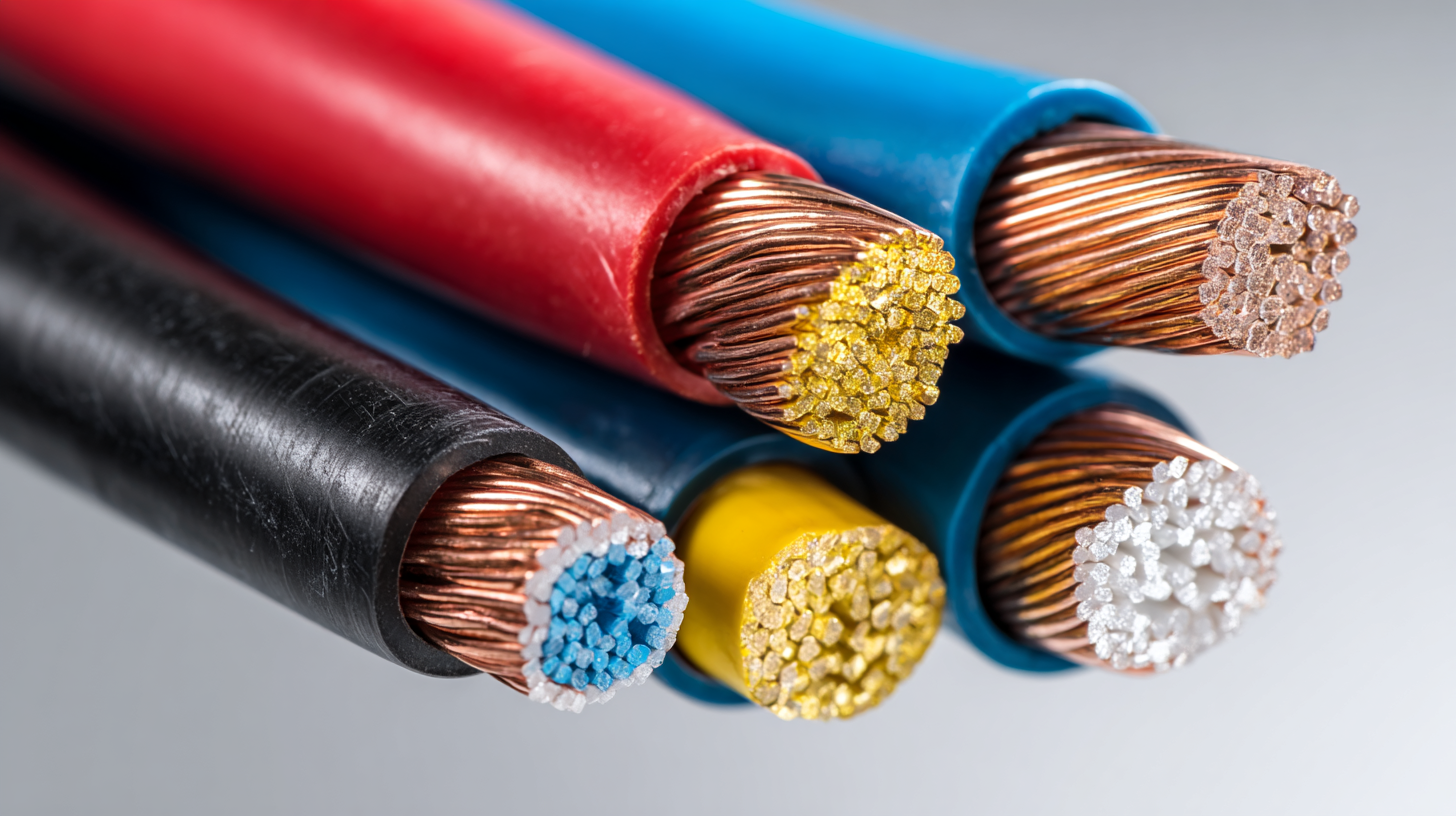

When it comes to tray cables, durability is a crucial factor that sets the best products apart in the global market. The unmatched durability of China's top tray cables ensures they can withstand harsh environmental conditions and heavy usage without compromising performance. This resilience not only extends the lifespan of the cables but also significantly reduces the need for frequent replacements, making them a cost-effective solution for various industries.

To maintain high standards of durability, manufacturers focus on using premium materials and rigorous testing processes. This commitment to quality results in cables that can withstand extreme temperatures, moisture, and physical stress. Tips for selecting the right tray cables include verifying the certification standards, reviewing manufacturer warranties, and ensuring compatibility with specific applications to avoid premature wear and tear.

Additionally, understanding the installation environment is vital. For instance, choosing cables designed for outdoor use can prevent damage from UV rays and moisture. Investing in tray cables with a proven track record of reliability will ultimately lead to safer and more efficient operations, highlighting the importance of durability in cable performance.

Innovative Manufacturing Processes Enhancing Quality Standards in Tray Cables

The manufacturing landscape is evolving at an unprecedented pace, particularly in the production of tray cables. Innovative processes are paving the way for enhanced quality standards that not only meet but exceed global market expectations. By incorporating advanced manufacturing techniques, producers are able to optimize their operations, significantly improving both reliability and performance. This shift not only ensures that products can withstand harsh environments but also addresses the growing demand for sustainability in the industry.

As companies commit to a circular economy, the focus on resource recovery and reusability has become paramount. However, the complexities surrounding materials recovery present both opportunities and challenges. In this context, robust sterilization methods play a crucial role in improving device reusability, while also adhering to stringent regulations. By overcoming these barriers, manufacturers not only enhance the quality of tray cables but also contribute to a more sustainable infrastructure industry, ensuring that innovation continues to drive progress forward.

Environmental Sustainability: A Growing Priority in Cable Production

Environmental sustainability has become a critical concern in the manufacturing industry, particularly in the production of tray cables. According to a report from the International Cablemakers Federation, approximately 60% of cable production emissions come from the use of materials and energy, highlighting the need for greener practices. Manufacturers in China, recognized for their high-quality tray cables, have started prioritizing sustainable methods to minimize their environmental impact. This shift not only aligns with global standards but also meets the demands from environmentally conscious markets.

In recent years, many Chinese cable manufacturers have invested in eco-friendly technologies and processes. For example, the adoption of recycled materials in cable insulation and the use of advanced energy-saving machinery have been reported to reduce carbon emissions by up to 30%. The increasing implementation of environmentally sustainable practices is paving the way for a more responsible manufacturing sector in China, which is essential for maintaining competitiveness in the global market. As businesses prioritize environmental sustainability, the focus on quality in tray cable production will continue to grow, forging a path toward a more sustainable future without compromising on performance.

Uncompromising Quality in Best Tray Cables Made in China for the Global Market - Environmental Sustainability: A Growing Priority in Cable Production

| Cable Type | Material | Voltage Rating (V) | Environmental Certifications | Recycling Type | Production Year |

|---|---|---|---|---|---|

| Low Voltage Tray Cable | PVC | 600 | RoHS, CE | PVC Recycling | 2023 |

| Medium Voltage Tray Cable | Cross-Linked Polyethylene | 15000 | UL, ISO 14001 | PE Recycling | 2023 |

| Instrumentation Tray Cable | Low Smoke Zero Halogen | 300 | NFPA, IEC | LSZH Recycling | 2023 |

| High Voltage Tray Cable | EPR | 34500 | NEMA, CSA | EPR Recycling | 2023 |

Global Compliance: Meeting International Standards for Tray Cables

In the world of electrical installations, tray cables play a crucial role in ensuring safety and efficiency. As the demand for high-quality tray cables grows globally, manufacturers in China are stepping up to meet international standards. Compliance with these standards is not just a legal requirement; it enhances the reputation of products in competitive markets. Companies that prioritize quality assurance demonstrate their commitment to producing reliable solutions for diverse applications, from industrial sites to commercial buildings.

Tip: When selecting tray cables, look for certifications such as UL, IEC, or RoHS compliance. These certifications indicate that the products have been rigorously tested and meet essential safety and performance requirements.

The global market is becoming increasingly interconnected, and adherence to international standards is vital for manufacturers exporting tray cables. Implementing stringent quality control processes and regular audits ensures that products meet the expected benchmarks across different regions. This proactive approach allows manufacturers to adapt to varying local regulations and customer needs, ultimately fostering trust among clients and stakeholders.

Tip: Consider conducting audits of suppliers to ensure they uphold quality standards and comply with global regulations. This practice not only mitigates risks but also strengthens the supply chain.

Cost-Effectiveness: Balancing Quality and Affordability in the Global Market

In the competitive landscape of tray cables, finding the right balance between quality and affordability is essential for global market success. According to a recent report by Grand View Research, the global tray cable market size was valued at approximately $3.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. This impressive growth underscores the increasing demand for high-quality, cost-effective cable solutions that meet industry standards.

When sourcing tray cables from China, manufacturers must prioritize both the materials used and the production processes. High-quality materials ensure durability and performance, while cost-effective manufacturing techniques can significantly reduce production costs, allowing companies to offer competitive pricing without sacrificing quality. Industry experts suggest that investing in advanced manufacturing technology can yield substantial long-term savings and enhance product reliability.

Tip: When evaluating tray cable suppliers, consider their certifications and compliance with international standards such as IEC and UL. This not only ensures quality but also opens opportunities for a wider market reach.

Another key factor is supplier relationships. Building strong partnerships with manufacturers can lead to better pricing and more favorable terms. Effective communication plays a vital role in negotiating costs and ensuring that both quality and budget requirements are met.

Tip: Regularly review supplier performance and market trends to adapt quickly to changes in pricing or material availability, helping to maintain a competitive edge.