2025 Top Electrical Cable Tray Trends You Need to Know

As we look ahead to 2025, the landscape of electrical cable tray systems is evolving rapidly to meet the demands of modern infrastructure and sustainable practices. Industry expert Dr. Lisa Johnson, a distinguished figure in electrical engineering, emphasizes the significance of these changes: "The future of electrical cable trays lies in their ability to enhance efficiency and safety while reducing environmental impact." This statement resonates in an era where both technology and environmental consciousness are pivotal to industrial growth.

The trends in electrical cable tray design are not merely about innovation but also about adapting to the needs of diverse industries, including telecommunications, construction, and renewable energy. With advancements in material science and manufacturing processes, we are witnessing a shift towards lightweight, durable, and more efficient cable management solutions. Moreover, the integration of smart technology within cable trays promises to optimize performance and monitoring, making them integral components in advanced electrical systems.

As we delve deeper into the top trends that will shape the electrical cable tray industry in the coming years, it becomes crucial to understand not only the technological advancements but also the implications they have for safety, efficiency, and sustainability in electrical installations.

Emerging Materials in Electrical Cable Tray Manufacturing for 2025

As we move towards 2025, the electrical cable tray industry is set to witness significant advancements in material science that promise to enhance performance and sustainability. One emerging trend is the development of eco-friendly materials that minimize environmental impact while maintaining structural integrity. Manufacturers are increasingly exploring the use of recycled composites and bioplastics, which offer both durability and a reduced carbon footprint. These innovative materials not only align with global sustainability goals but also meet the stringent demands of modern electrical installations.

Another noteworthy trend is the incorporation of advanced metallic coatings designed to improve resistance against corrosion and extreme temperatures. Such coatings enhance the longevity of cable trays, making them suitable for diverse industrial applications, from manufacturing plants to harsh outdoor environments. Additionally, the integration of smart technologies is becoming prevalent, allowing for real-time monitoring of the cable tray systems. This can lead to enhanced safety and efficiency as operators can manage maintenance proactively, reducing downtime and operational costs. These emerging materials and technologies herald a new era in the cable tray landscape, ensuring that electrical infrastructures are both resilient and responsible.

Sustainability Trends in Cable Tray Design and Production

Sustainability is becoming increasingly critical in the design and production of electrical cable trays as industries prioritize eco-friendly practices. According to a recent report by the Environmental Protection Agency (EPA), the use of recycled materials in manufacturing can reduce energy consumption by up to 75%. This trend has prompted manufacturers to explore innovative materials such as aluminum and steel that can be recycled effectively. These choices not only minimize the environmental footprint but also enhance the durability and longevity of cable trays, contributing to a more sustainable lifecycle.

Moreover, energy-efficient production methods are gaining traction. The International Energy Agency (IEA) has stated that transitioning to renewable energy sources for manufacturing processes can cut greenhouse gas emissions significantly. Many manufacturers are now investing in solar and wind energy solutions to power their facilities, resulting in an average reduction of 30% in overall emissions. This shift not only aligns with global sustainability goals but also caters to an increasingly environmentally conscious consumer base that favors products with a lower ecological impact. As the demand for sustainable cable trays continues to rise, the industry is poised for transformation, driven by both regulatory pressures and market dynamics.

Innovative Installation Techniques for Electrical Cable Trays

Innovative installation techniques for electrical cable trays are transforming the way we approach modern electrical infrastructure. One emerging trend is the use of modular components, which simplify the assembly process and enhance adaptability. These pre-fabricated sections can be easily customized on-site to fit specific project requirements, reducing installation time and labor costs. Additionally, the ability to reconfigure these modular trays means they can accommodate future upgrades with minimal disruption.

Another significant development in installation techniques is the integration of advanced materials, such as lightweight composites and corrosion-resistant alloys. These materials not only provide durability but also make the installation process more efficient. The reduced weight allows for easier handling and reduces the need for heavy lifting equipment, which can shorten project timelines. Furthermore, the design innovations associated with these materials, such as improved flexibility and conductivity, contribute to more effective cable management and reduce the risk of overheating.

Lastly, the adoption of digital tools and augmented reality (AR) during the installation of electrical cable trays is gaining traction. These technologies facilitate precise planning and visualization, enabling installers to detect potential issues before physical installation begins. By leveraging AR, teams can simulate the installation process, ensuring optimal layout and minimizing errors. This forward-thinking approach not only enhances accuracy but also maximizes the efficiency of the installation, paving the way for smarter and more sustainable electrical systems.

Smart Technologies and Automation in Cable Tray Systems

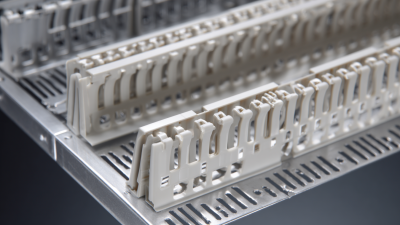

The evolution of cable tray systems is being significantly influenced by the integration of smart technologies and automation. As industries increasingly lean towards digital transformation, the incorporation of intelligent systems within cable tray solutions enhances efficiency and reliability in electrical installations. With the advent of sensors and IoT (Internet of Things) devices, cable trays can now monitor environmental conditions, including temperature and humidity, which ensures optimal performance and proactive maintenance. This technology allows for real-time data collection, enabling facility managers to make informed decisions and streamline operations.

Moreover, automation within cable tray systems is revolutionizing installation and management processes. Automated cable management solutions simplify the routing and organization of electrical cables, reducing human error and improving safety. By employing robotics and automated control systems, the installation phase is expedited, allowing for seamless integration in various environments, from commercial buildings to industrial plants. These advancements not only decrease labor costs but also enhance the adaptability of cable trays to changing project requirements, paving the way for more flexible and intelligent infrastructure in the future.

2025 Top Electrical Cable Tray Trends

Regulatory Changes Impacting Electrical Cable Tray Specifications in 2025

In 2025, regulatory changes are set to significantly influence electrical cable tray specifications, shaping the design and use of these essential components in various industries. The 2023 report from the International Electrotechnical Commission (IEC) indicates a pivotal shift towards stricter safety standards and environmental regulations. With a projected increase in infrastructure development, these regulations demand that cable trays not only comply with safety norms but also contribute to energy efficiency and sustainability.

One of the key areas of focus is the advent of materials that meet the new compliance standards while minimizing environmental impact. According to the Electrical Association's recent survey, 75% of manufacturers are channeling their efforts into developing cable trays made from recyclable and sustainable materials, reflecting a growing trend towards eco-friendly construction practices. Additionally, the introduction of new testing protocols aimed at enhancing fire resistance and load-bearing capabilities will ensure that electrical installations are safer and more reliable. As the industry adapts to these changes, it is essential for stakeholders to stay informed about updated specifications to ensure compliance and maintain operational efficiency.

2025 Top Electrical Cable Tray Trends You Need to Know - Regulatory Changes Impacting Electrical Cable Tray Specifications in 2025

| Trend | Description | Regulatory Impact | Expected Changes |

|---|---|---|---|

| Increased Sustainability | Focus on eco-friendly materials and practices. | New certifications required for sustainable materials. | Adoption of recycled metal and corrosion-resistant coatings. |

| Modular Designs | Flexible cable tray systems for easy installation. | Updated codes may specify broader dimensions. | Pre-assembled components for rapid deployment. |

| Technological Integration | Smart cable trays with sensors for monitoring. | Regulations may require tracking for maintenance. | Installation of IoT devices for real-time data. |

| Fire Safety Standards | Enhanced fire resistance specifications for trays. | New material requirements to meet fire codes. | Use of flame-retardant coatings and insulation. |

| Increased Load Capacity | Designs capable of supporting heavier cables. | Revised limits on weight-bearing capacities. | Use of reinforced materials for better support. |

Related Posts

-

How to Choose the Right Cable Tray for Your Electrical Installation Needs

-

5 Essential Tips for Choosing the Right Wire Cable Tray for Your Project

-

How to Choose the Right Cable Tray for Your Electrical Wiring Needs

-

How to Choose the Best Wire Cable Tray for Your Industrial Needs

-

10 Essential Checklist Items for Sourcing the Perfect Basket Cable Tray for Your Project

-

How to Select the Right Plastic Cable Tray for Your Electrical Installation Needs