How to Select the Right Plastic Cable Tray for Your Electrical Installation Needs

When it comes to electrical installations, the importance of selecting the right components cannot be overstated. One critical element that often goes unnoticed is the plastic cable tray. These trays not only support and manage cables but also play a vital role in ensuring safety and efficiency in electrical systems. With a variety of options available in the market, understanding how to choose the best plastic cable tray for your specific installation needs is essential. Factors such as material durability, load capacity, and environmental compatibility must be carefully considered. This guide will provide an overview of the key features to look for in plastic cable trays, helping you make an informed decision that aligns with both your project requirements and best practices in the industry.

Understanding the Different Types of Plastic Cable Trays Available in the Market

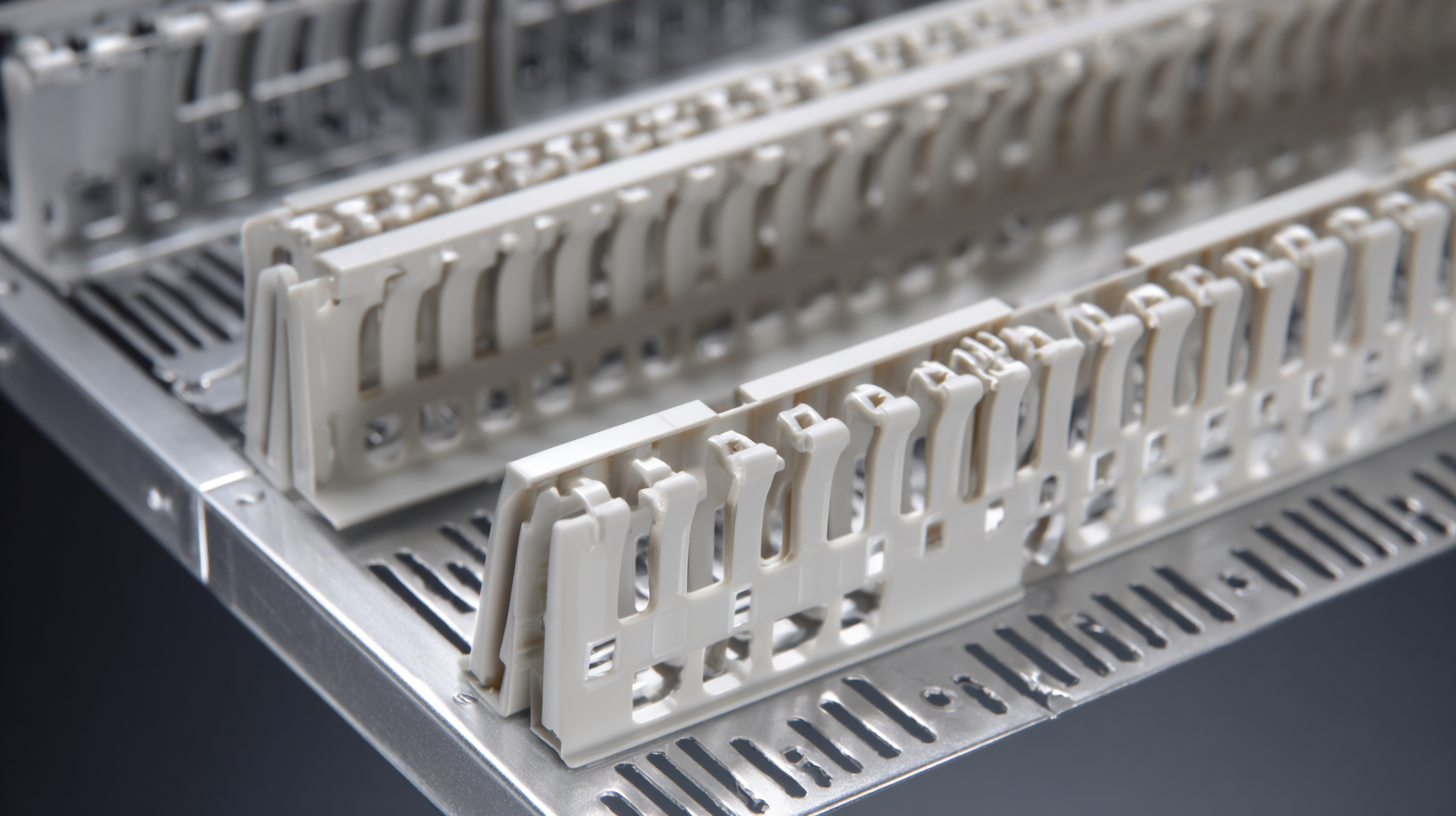

When selecting the right plastic cable tray for electrical installations, it’s essential to understand the various types available in the market. Plastic cable trays come in different materials, including PVC and fiberglass, each offering unique benefits tailored to specific applications. PVC trays are often favored for their lightweight nature, corrosion resistance, and ease of installation, making them ideal for both indoor and outdoor settings. In contrast, fiberglass trays provide greater strength and are excellent for environments where high levels of durability and resistance to harsh chemicals are required.

The growing focus on renewable energy and sustainable practices has further influenced the demand for plastic cable trays. As the renewable energy sector expands with the adoption of solar, wind, and hydropower technologies, the need for reliable cable management systems becomes increasingly critical. Efficient wiring systems not only ensure safety and performance but also align with eco-friendly initiatives. Therefore, understanding the different types of plastic cable trays and their suitability for various electrical installations is crucial for meeting both operational needs and sustainability goals in the evolving energy landscape.

Evaluating Load Capacity and Supporting Requirements for Cable Trays

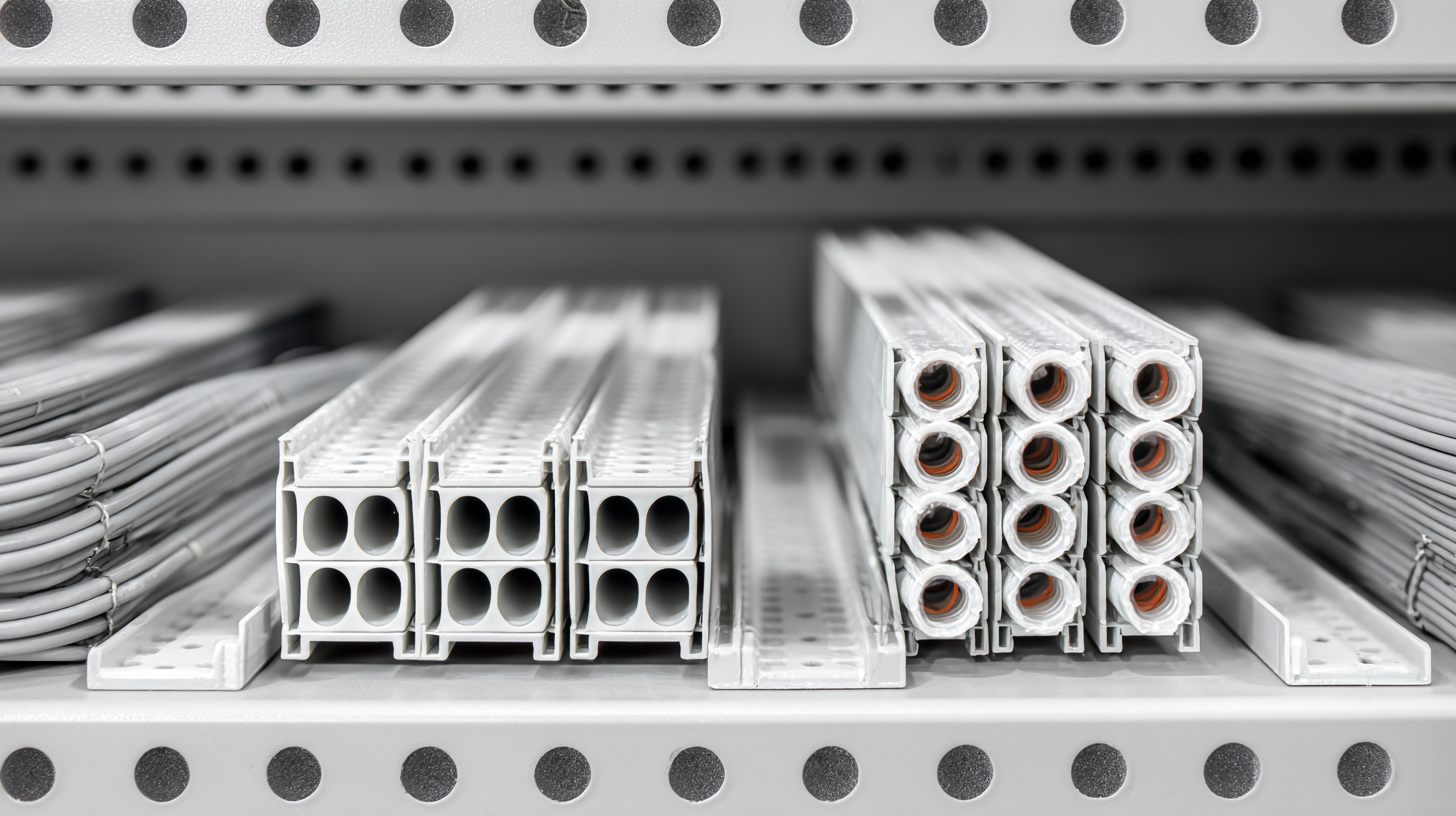

When selecting a plastic cable tray for your electrical installation, evaluating load capacity and supporting requirements is crucial. The load capacity dictates the amount of weight the tray can safely hold, which includes the combined weight of all cables and any additional components. It's essential to consult manufacturer specifications for load ratings and consider factors such as the number and types of cables you plan to install.

**Tips:** Always overestimate your load needs. If you plan to add more cables in the future, choose a tray that can handle the maximum anticipated load. Additionally, ensure that the supporting requirements are adequately met. Check if the installation site can support the weight of the tray when fully loaded, and use proper brackets or supports to prevent sagging or structural failure.

Proper installation of cable trays involves understanding the guidelines surrounding spacing and support intervals. Check local codes, as they often dictate minimum support distances based on the tray size and load. Adequate support not only prolongs the life of the cables but also ensures safety in your electrical installations. Choosing the right support solution can prevent costly damage and keep your system functioning optimally.

Load Capacity of Different Plastic Cable Trays

Assessing Environmental Conditions and Their Impact on Tray Selection

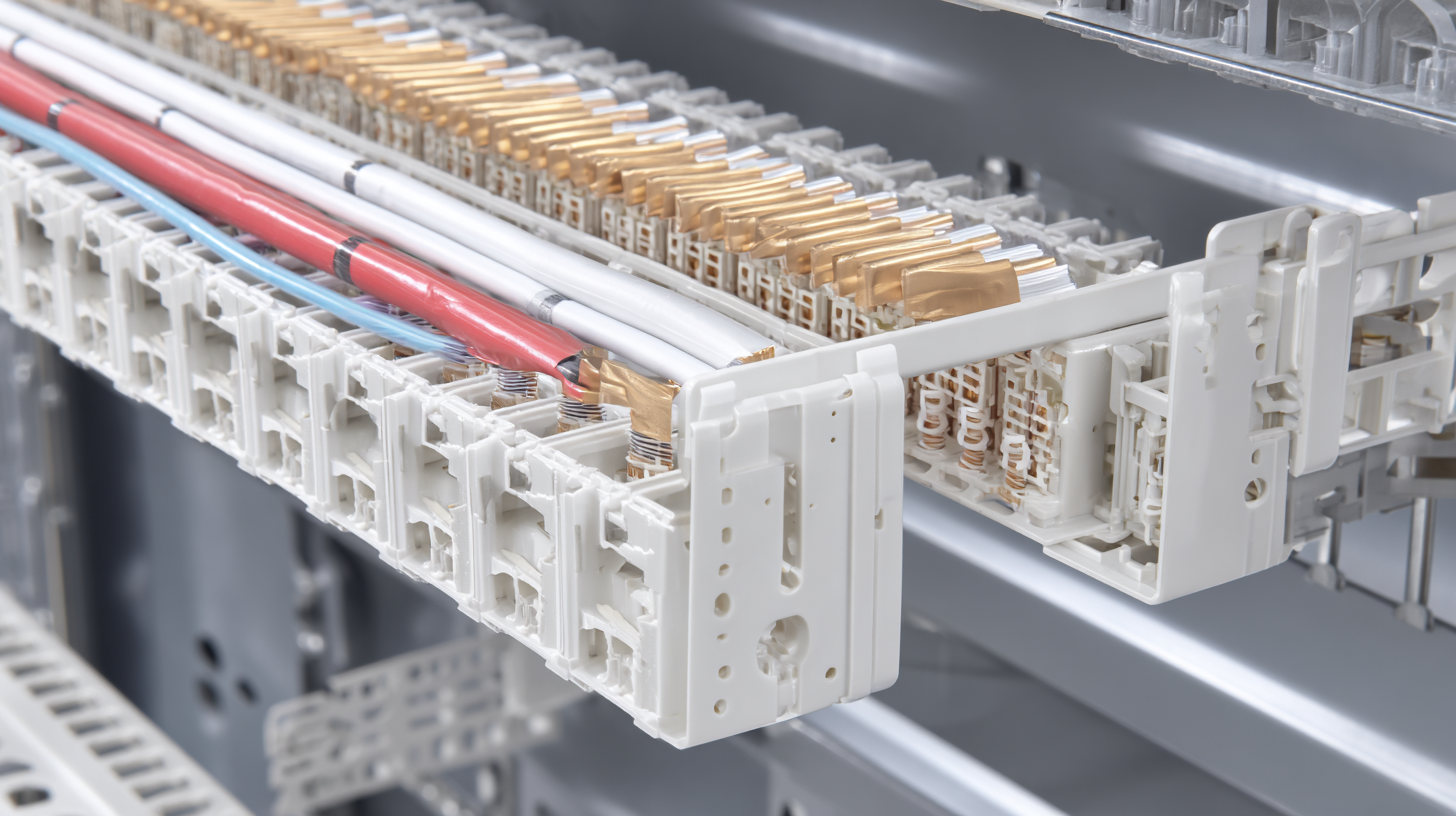

When selecting the right plastic cable tray for electrical installations, understanding the environmental conditions is paramount. Various factors such as temperature, humidity, and exposure to chemicals can significantly impact the performance and longevity of the cable trays. For instance, in coastal areas where saltwater exposure is prevalent, choosing trays made from UV-stabilized materials becomes essential to prevent degradation. Similarly, environments with high humidity levels require trays that can resist corrosion and mold growth, ensuring optimal function over time.

Additionally, the potential for physical impact or abrasion in certain settings should also be assessed. In industrial applications where heavy machinery operates, opting for thicker, reinforced trays can provide the necessary durability. Furthermore, consider the installation location; whether indoors or outdoors may influence the material choice. Understanding these environmental challenges allows for a more informed selection process, ensuring that the cable trays not only meet electrical requirements but also withstand the specific conditions they will encounter.

Considering Maintenance and Installation Ease of Plastic Cable Trays

When selecting plastic cable trays for electrical installations, considering maintenance and installation ease is paramount. Plastic trays offer distinct advantages over traditional materials, especially in scenarios where agility and adaptability are required. Their lightweight nature allows for quick installation, reducing labor costs and installation time. These trays can often be installed using simple fastening methods, minimizing the need for specialized tools or machinery, which streamlines the setup process for contractors.

Moreover, maintenance considerations play a crucial role in deciding on the right plastic cable tray. Unlike metal trays that may require regular inspections for corrosion or rust, plastic options are generally resistant to environmental factors, making them ideal for both indoor and outdoor applications. This durability against moisture and chemicals can lead to lower maintenance costs and less downtime during operation. An understanding of the specific installation environment—such as exposure to chemicals or extreme temperatures—will further aid in selecting the appropriate plastic tray, ensuring that it not only meets initial installation needs but also maintains performance over time.

Cost Analysis: Balancing Quality and Budget for Your Installation Needs

When selecting a plastic cable tray for your electrical installation, a thorough cost analysis is essential to achieve the perfect balance between quality and budget. Quality materials often come at a higher price, but they can save you money in the long run by ensuring durability and reducing maintenance costs. It is crucial to evaluate the specifications of various trays, comparing their load capacities and resistance to environmental factors, as optimal performance can mitigate future expenses.

Tips: Consider choosing trays that comply with industry standards; this can prevent costly reinstallation and ensure safety. Additionally, seek out vendors offering cost-effective bulk purchasing options or discounts for larger orders, as this can stretch your budget further while still allowing you to invest in quality products.

Another aspect to consider is the installation process itself. Using high-quality trays can facilitate easier installation, potentially reducing labor costs. Remember to calculate the total cost, which includes not just the purchase price but also installation and future maintenance expenses. Being strategic about your choices will help you select a plastic cable tray that meets both your quality expectations and budget constraints effectively.

Related Posts

-

2025 Global Market Insights: Transforming Spaces with the Best Plastic Cable Tray Solutions

-

How to Choose the Best Wire Cable Tray for Your Industrial Needs

-

Exploring Alternative Solutions to the Best Wire Basket Cable Tray

-

7 Essential Tips for Choosing the Right Wire Basket Cable Tray for Your Business Needs

-

How to Choose the Best PV Cable for Maximum Solar Energy Efficiency

-

5 Essential Tips for Choosing the Right Wire Cable Tray for Your Project