10 Essential Checklist Items for Sourcing the Perfect Basket Cable Tray for Your Project

In the world of electrical installations, the selection of the right cable management solution is critical for ensuring both efficiency and safety. According to a recent industry report by Freedonia Group, the market for cable management systems, including basket cable trays, is projected to reach $4.6 billion by 2024, driven by a growing emphasis on infrastructure development and the increasing complexity of modern electrical systems. Choosing the perfect basket cable tray for your project involves more than just aesthetics; it requires careful consideration of factors such as load capacity, material properties, and compliance with safety standards. This blog will provide you with a comprehensive checklist of ten essential items to evaluate, ensuring that you make an informed decision that aligns with your project's needs and regulatory requirements. Whether you are working on a commercial building or an industrial site, understanding these key elements will help you source the ideal basket cable tray to support your electrical installations effectively.

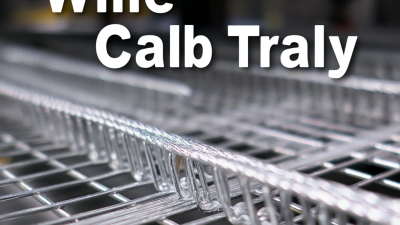

Key Factors to Consider When Choosing a Basket Cable Tray for Your Project

When selecting a basket cable tray for your project, it's essential to consider several key factors to ensure you choose the right product. First and foremost, evaluate the material options available.

Steel, aluminum, and stainless steel are the three primary materials in the market, each offering unique properties like strength, corrosion resistance, and weight. For instance, aluminum trays are lightweight and resistant to rust, making them suitable for indoor applications, while steel may be preferable for heavier loads outdoors.

Steel, aluminum, and stainless steel are the three primary materials in the market, each offering unique properties like strength, corrosion resistance, and weight. For instance, aluminum trays are lightweight and resistant to rust, making them suitable for indoor applications, while steel may be preferable for heavier loads outdoors.

Next, it's vital to assess the design and type of the cable tray. Ladder trays and basket trays serve different purposes; while ladder trays offer superior support for heavy cabling, basket trays are ideal for lighter applications and allow for better airflow.

Consider the specific requirements of your project, such as cable size and weight, to determine the appropriate design.

Tip: Always check for compliance with local regulations and standards when sourcing cable trays. Additionally, consult with suppliers who can provide insights into the latest technologies and innovations in cable tray design, ensuring that you make an informed decision that aligns with your project's needs.

Understanding Different Materials Used in Basket Cable Trays

When selecting a basket cable tray for your project, understanding the different materials used in their construction is crucial. Basket cable trays are typically made from a variety of materials, each offering unique benefits that cater to various project requirements. For instance, steel is the most common material used, known for its exceptional strength and durability. Galvanized steel trays provide excellent corrosion resistance, making them ideal for environments where moisture or chemical exposure is a concern. Additionally, stainless steel options offer enhanced longevity in harsh conditions, making them suitable for industrial applications.

On the other hand, aluminum basket cable trays present a lighter alternative without compromising on strength. They are particularly useful in applications where weight is a significant factor, such as in overhead installations. Furthermore, aluminum trays are resistant to rust, which extends their lifespan in outdoor settings. For projects requiring a more aesthetic appeal, powder-coated options can provide a range of colors while ensuring the tray’s durability. By understanding these materials and their specific applications, project managers can make informed decisions that enhance both functionality and longevity of the cable management system.

Evaluating Load Capacity and Strength Requirements for Your Installation

When sourcing a basket cable tray, evaluating load capacity and strength requirements is critical to ensure compliance with safety standards and the performance demands of your installation. According to the National Electrical Manufacturers Association (NEMA), the load rating for cable trays can vary significantly based on factors such as tray material, size, and configuration. For instance, a standard 12-inch wide steel cable tray typically supports a maximum load of around 80 pounds per linear foot, while aluminum variants present slightly lower capacities due to their lightweight nature.

Incorporating factors such as environmental conditions and the types of cables used is also essential. A 2022 report by the International Electrotechnical Commission (IEC) highlights that factors like exposure to corrosive environments or extreme temperatures can significantly impact the structural integrity of cable trays. It is crucial to assess the combined weight of all cables and any additional equipment that might be installed within the tray to avoid overloading. Properly understanding these specifications will help in selecting the appropriate cable tray that not only meets installation needs but also offers long-term durability and safety.

Assessing Compatibility with Existing Electrical Systems and Layout

When selecting a basket cable tray for your project, assessing compatibility with existing electrical systems and layout is crucial. According to the National Electrical Manufacturers Association (NEMA), nearly 40% of electrical installation failures are attributed to improper coordination with existing infrastructure. Therefore, it is important to evaluate your current systems, including cable types and load requirements, to ensure that the new tray can accommodate them.

Additionally, industry standards, such as those outlined by the Institute of Electrical and Electronics Engineers (IEEE), recommend that any new cable management solutions should align with the spatial configurations and electrical load capacities of existing systems. For example, if your current setup involves high-capacity cables, selecting a basket tray with adequate depth and width is essential to maintaining proper airflow and minimizing overheating risks. A thorough compatibility assessment not only ensures efficiency but also prolongs the lifespan of the overall system, leading to cost savings of up to 20% in maintenance over time.

Importance of Compliance with Safety Standards and Regulations

When sourcing a basket cable tray for your project, compliance with safety standards and regulations should be at the forefront of your decision-making process. Ensuring that your selected tray meets industry standards, such as those set by the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL), is critical. According to a report from the Occupational Safety and Health Administration (OSHA), non-compliance with safety standards resulted in over 5,000 workplace accidents in the electrical sector in 2021 alone. This highlights the importance of selecting cable management solutions that not only meet regulatory requirements but also enhance the overall safety of the workplace.

Moreover, selecting a basket cable tray that complies with safety standards can significantly boost project efficiency and longevity. A study by the National Fire Protection Association (NFPA) indicates that systems adhering to strict safety regulations can reduce the risk of fire hazards and electrical failures by up to 40%. This not only safeguards your project but can also lead to considerable cost savings over time by minimizing maintenance and replacement needs. Therefore, prioritizing compliance when selecting a basket cable tray is not just a regulatory necessity, but a vital step towards ensuring safety and reliability in any electrical installation.

Related Posts

-

How to Choose the Right Cable Tray for Your Electrical Installation Needs

-

Exploring Innovative Alternatives to the Best Cable Rack Solutions for Efficient Organization

-

Solutions for Optimal Cable Management with Best Cable Basket

-

Discover Premium Cable Racks from China's Leading Manufacturing Hub

-

Quality Driven Chinese Manufacturing in Global Leader Best Cable Management Tray

-

How to Choose the Best Wire Cable Tray for Your Industrial Needs