Discover Premium Cable Racks from China's Leading Manufacturing Hub

In today's interconnected world, efficient cable management has become paramount, especially for industries relying on advanced technology and data systems. A recent report by MarketsandMarkets projects that the global cable management market is set to reach $30 billion by 2025, fueled by the increasing demand for organized solutions in data centers and telecommunications. As companies seek to optimize their operations and ensure safety and reliability in their installations, the role of high-quality cable racks cannot be overstated.

China, recognized as a manufacturing powerhouse, is leading the charge in producing premium cable racks that meet international standards for durability and functionality. This blog will explore the diverse options available from this manufacturing hub, highlighting the reasons why investing in quality cable racks is essential for modern infrastructure.

Explore the Growth of the Cable Rack Industry in China: Key Statistics and Trends

The cable rack industry in China is experiencing a significant boost, driven by rising demand in various sectors, including telecommunications and construction. According to recent market data, the cable tray market size is projected to grow substantially from 2024 to 2032, with an expected CAGR that underscores the industry's vitality. This growth is fueled by advancements in material technology and increased emphasis on efficient cable management solutions in China's rapidly expanding infrastructure.

Moreover, statistics reveal that the global wires and cables market is also on an upward trend, with the U.S. market valued at approximately USD 31.93 billion in 2024, and anticipated to grow at a CAGR of 5.9% from 2025 to 2030. This reflects the global influence of China’s manufacturing capabilities, where high-quality cable racks are being produced to meet both local and international standards. The strategic positioning of China as a manufacturing powerhouse is not only elevating its cable rack industry but also contributing to the overall growth of the cable management sector globally.

Understanding the Types of Premium Cable Racks: A Comprehensive Guide for Buyers

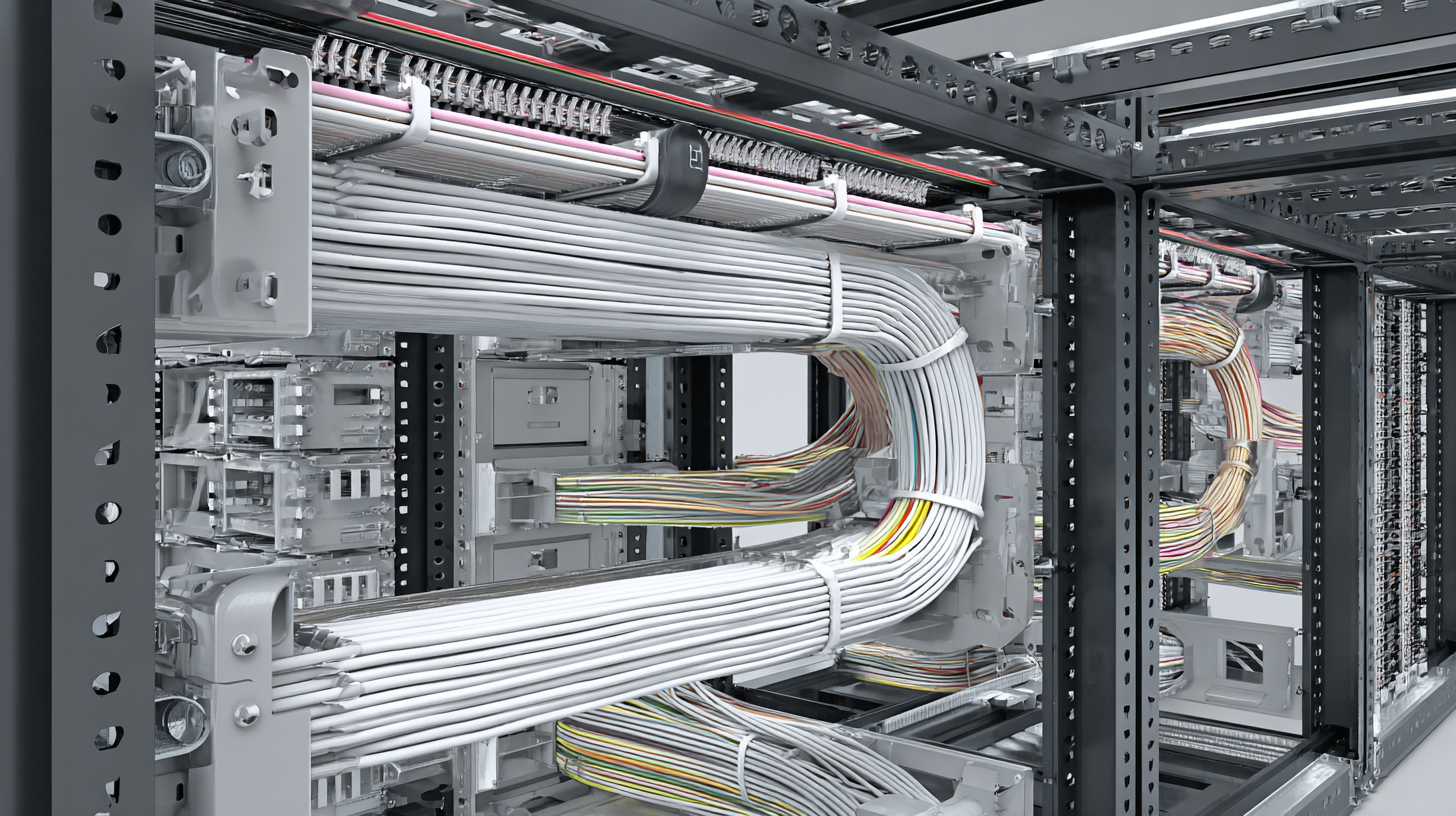

Cable racks are crucial in managing cables efficiently in various industries, from telecommunications to data centers. There are different types of premium cable racks available, each designed for specific needs. For instance, vertical cable racks are ideal for high-density environments, accommodating a large number of cables while saving space. According to a recent market report, the global cable management market is expected to grow at a CAGR of 12.2% between 2021 and 2026, reflecting an increasing demand for organized and efficient cable solutions.

Another popular type is horizontal cable racks, perfect for applications where cable accessibility is a priority. These racks often come with adjustable features, allowing customization based on the user's requirements. Data from industry experts indicate that improper cable management can lead to increased operational costs, as disorganized setups can slow maintenance and troubleshooting processes. This highlights the importance of selecting the right premium cable rack to enhance operational efficiency and minimize downtime in any technical environment.

Buyers should also consider specialized racks, such as those equipped with cooling features or integrated power distribution. As the industry evolves, manufacturers in China's leading manufacturing hub are innovating designs that cater to different configurations and technologies, ensuring that businesses have access to cutting-edge solutions for their cable management needs.

Evaluating Manufacturing Standards: What to Look for in Cable Racks from China

When considering cable racks from China, it's crucial to evaluate the manufacturing standards that ensure product quality and reliability. According to a report by the International Standards Organization (ISO), adherence to manufacturing protocols can significantly impact the durability and performance of cable racks. A study indicated that products meeting ISO 9001 standards are 25% more likely to perform well over a five-year period compared to those not adhering to such rigorous standards.

Another essential aspect to consider is the material used in production. Research by the American Society for Testing and Materials (ASTM) shows that cable racks made from high-grade materials, such as stainless steel or heavy-duty aluminum, exhibit superior resistance to corrosion and mechanical stress. This is particularly important in environments where cable racks face harsh conditions. Furthermore, manufacturers that implement strict quality control measures can guarantee a failure rate of less than 2%, which is vital for maintaining operational efficiency in industrial settings. By focusing on these manufacturing standards, buyers can make informed decisions when sourcing premium cable racks from China.

Production Standards Evaluation for Cable Racks

Cost Analysis: The Economic Benefits of Sourcing Cable Racks from China's Manufacturing Hubs

When considering the sourcing of premium cable racks, China's manufacturing hubs present an unmatched economic advantage. The lower production costs in these regions stem from access to abundant raw materials, a skilled labor force, and advanced manufacturing technologies. This combination not only allows Chinese manufacturers to produce high-quality cable racks at competitive prices but also enables businesses across the globe to reduce their operational expenditures dramatically. As a result, companies can allocate savings to other critical areas, such as marketing and product development, thereby enhancing their overall market position.

Moreover, the rapid turnaround times and scalable production capabilities in China further contribute to cost efficiency. Manufacturers in these hubs can swiftly adjust output in response to fluctuating demand, ensuring that clients receive products when needed without incurring excessive storage costs. Such flexibility is particularly beneficial in today’s fast-paced market environments, where meeting customer expectations is paramount. By leveraging these economic benefits, businesses that source cable racks from China not only gain financial advantages but also a strategic edge over their competitors, allowing them to thrive in an increasingly competitive landscape.

Navigating the Supply Chain: Best Practices for Importing Premium Cable Racks from China

When importing premium cable racks from China, navigating the supply chain efficiently is crucial to ensure timely delivery and quality assurance. One of the best practices is to conduct thorough research on prospective manufacturers. Look for companies with a strong reputation in the industry, verified certifications, and a portfolio of completed projects. Networking with industry professionals and attending trade fairs can provide insights into emerging suppliers and innovative product offerings.

Tip: Always request samples before placing bulk orders. This allows you to verify the quality of the cable racks, ensuring they meet your specifications and standards.

Another essential aspect of supply chain management is understanding the logistics involved. Familiarize yourself with shipping processes, customs regulations, and potential tariffs that may apply. Building a reliable relationship with a logistics partner can help streamline the shipping process and reduce lead times.

Tip: Employ an experienced freight forwarder who can navigate the complexities of international shipping, ensuring all documentation is in order and mitigating the risk of delays at customs.