2025 How to Choose the Right Tray Cable for Your Electrical Projects

In the realm of modern electrical installations, the choice of the right tray cable is pivotal to ensuring safety, efficiency, and reliability. Tray cables, typically utilized in industrial and commercial environments, are designed to be used in a cable tray system, significantly enhancing the organization and protection of electrical conductors. According to the National Electrical Manufacturers Association (NEMA), the demand for high-performance tray cables is projected to witness a growth of approximately 5% annually, reflecting their increasing importance in contemporary electrical infrastructure.

As electrical projects evolve, the complexities surrounding cable selection have intensified, making it imperative for engineers and professionals to be equipped with the latest knowledge pertaining to tray cable specifications. An analysis by the Electrical Contractors Association indicated that improper cable selection can lead to up to 35% of electrical failures, underscoring the necessity for due diligence when selecting suitable tray cables for specific applications. Factors such as environmental conditions, load capacity, and installation methods must be carefully considered to ensure optimal performance and compliance with relevant standards.

Navigating the myriad of options available can be daunting, but with the right guidelines and an understanding of the technical requirements, professionals can make informed decisions that uphold the integrity of their electrical projects. This article aims to provide a comprehensive insight into the selection process of tray cables, equipping readers with the knowledge necessary to make the best choices for their electrical needs.

Understanding Tray Cable Types: NEC Guidelines and Industry Standards

When selecting the right tray cable for electrical projects, understanding the various types available and the associated National Electrical Code (NEC) guidelines is crucial. Tray cables, commonly used in industrial settings, are designed to be routed through cable trays and exposed environments. The NEC outlines specific requirements for these cables, emphasizing factors such as environmental resistance, conductor materials, and installation methods. Familiarizing yourself with these codes not only ensures compliance but also guarantees the safety and performance of electrical installations.

There are several different types of tray cables available, each suited for specific applications. For instance, Type TC (Tray Cable) is widely used for power distribution in industrial environments due to its robust construction and resistance to harsh conditions. Similarly, Type TC-ER adds flexibility with its ability to be used for both exposed and non-exposed applications. Considerations such as cable insulation type and the number of conductors play a significant role in the selection process. Industry standards dictate not just the physical properties of the cables but also the guidelines for installation in various scenarios, enabling electrical professionals to make informed decisions tailored to their project requirements.

Factors Influencing Tray Cable Selection: Environment and Application Needs

When selecting tray cables for electrical projects, understanding the environmental conditions and specific application needs is crucial. One of the primary factors to consider is the location where the cables will be installed. For instance, cables intended for outdoor use should have robust insulation and sheathing to withstand UV exposure and temperature fluctuations. Conversely, indoor installations may prioritize flexibility and ease of installation, making a different type of insulation more appropriate. Additionally, the presence of chemicals, moisture, or extreme temperatures can significantly influence the choice of materials, as these factors can affect cable durability and safety.

Another important consideration is the electrical load and data transmission requirements of the application. Different projects may demand varying levels of voltage and current capacity, leading to the selection of cables with suitable conductors and gauges. It is also essential to assess the configuration of the cable trays, including their size and layout, to ensure compatibility with the selected cables. This is especially pertinent in industrial and commercial settings where space optimization can enhance system efficiency. By focusing on these environmental aspects and application needs, professionals can make informed decisions that enhance both performance and safety in their electrical installations.

2025 How to Choose the Right Tray Cable for Your Electrical Projects

| Cable Type | Application | Environmental Factors | Voltage Rating | Conductor Material | Insulation Type |

|---|---|---|---|---|---|

| Type AC | Industrial Equipment | Indoor, Low Moisture | 600V | Copper | PVC |

| Type TC | Control Circuits | Indoor/Outdoor, Moderate Moisture | 600V | Copper, Aluminum | XLPE |

| Type NM | Residential Wiring | Indoor, Dry Conditions | 300V | Copper | PVC |

| Type USE | Underground Service | Buried, Wet Conditions | 600V | Copper | Cross-linked polyethylene |

| Type SJO | Portable Equipment | Indoor/Outdoor, Flexible | 300V | Copper | Rubber |

Sizing and Ampacity: Calculating the Right Tray Cable for Your Project

When selecting tray cables for electrical projects, understanding the concepts of sizing and ampacity is crucial. Sizing refers to the selection of the appropriate wire gauge based on the total current that will pass through the conductor. According to the National Electrical Code (NEC), the ampacity, or the maximum amount of electrical current a cable can carry without overheating, varies significantly depending on several factors, including the type of insulation, the ambient temperature, and the installation conditions. For instance, a 500 MCM copper cable with THHN insulation has an ampacity of approximately 380 amps in free air but might have reduced ampacity when installed in a raceway or tray due to proximity to other heat-generating conductors.

Calculating the right tray cable involves not only determining the ampacity but also considering factors such as voltage drop and the total load required by the electrical system. The IEEE Standard 141, also known as the IEEE Green Book, provides guidelines on calculating voltage drop, which is essential for ensuring optimal system performance. For instance, a standard recommendation is to keep voltage drop under 3% for feeder circuits to maintain efficiency and protect equipment from potential damage. Properly calculating these factors ensures safety and reliability while optimizing the efficiency of the electrical system. Thus, careful consideration of sizing and ampacity is essential for choosing the right tray cable for your specific electrical projects.

Material Choices: Copper vs. Aluminum in Tray Cable Applications

When selecting tray cables for electrical projects, the choice of material can significantly impact performance and durability. Two of the most commonly used materials in tray cable applications are copper and aluminum, each offering distinct advantages and disadvantages.

Copper, known for its superior conductivity and reliability, is often favored for high-performance electrical systems. Its lower resistance means less energy loss and higher efficiency, making it an ideal choice for critical applications where consistent power delivery is essential. Additionally, copper's resistance to corrosion ensures longevity even in challenging environmental conditions.

On the other hand, aluminum is gaining traction due to its lightweight properties and lower cost. While it has a higher resistance compared to copper, aluminum's installation benefits make it an attractive option, especially in large-scale projects where weight considerations are critical. Moreover, advancements in aluminum alloy technologies have improved its conductivity and resistance to corrosion, making it a viable alternative for many applications.

Ultimately, the decision between copper and aluminum should be based on specific project requirements, budget constraints, and the intended environment, ensuring that the chosen tray cable will deliver the necessary performance and reliability.

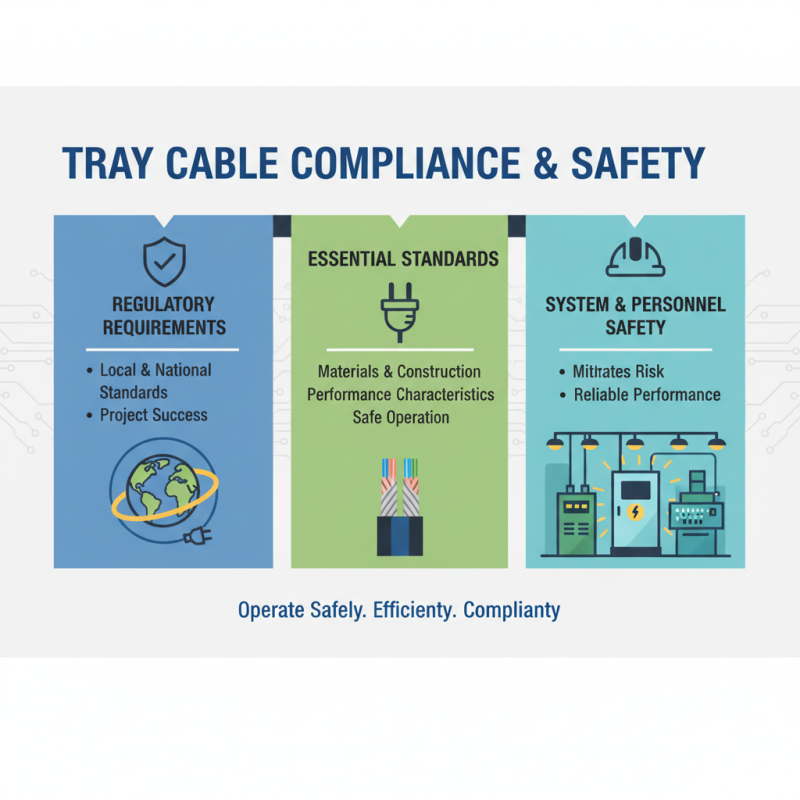

Compliance and Safety: Ensuring Tray Cable Meets Regulatory Requirements

When selecting tray cables for electrical projects, compliance and safety are paramount. Ensuring that the chosen cables meet local and national regulatory requirements is essential not only for project success but also for the safety of systems and personnel. Regulatory bodies often set forth specific standards that govern the materials, construction, and performance characteristics of tray cables. Understanding these standards helps in selecting cables that will operate safely and efficiently in their intended environment.

In addition to regulatory compliance, it is crucial to consider the environmental conditions the cables will be exposed to. Tray cables must be designed to withstand particular hazards, such as moisture, heat, and chemical exposure. Selecting cables that comply with codes like the National Electrical Code (NEC) and Underwriters Laboratories (UL) standards can significantly reduce risks associated with electrical failures or hazards. Careful assessment of these factors ensures that the tray cables not only conform to regulatory requirements but also contribute to the overall safety and longevity of the electrical system.

Related Posts

-

Uncompromising Quality in Best Tray Cables Made in China for the Global Market

-

Harnessing the Best Tray Cable from China to Lead Global Manufacturing Innovation

-

How to Choose the Best Wire Cable Tray for Your Industrial Needs

-

The future of solar cable innovations driving renewable energy growth and efficiency

-

How to Select the Right Plastic Cable Tray for Your Electrical Installation Needs

-

7 Essential Tips for Maximizing Efficiency with Wire Basket Trays