How to Choose the Right Ladder Tray for Your Project?

Choosing the right ladder tray for your project can be a challenging task. The options available may seem overwhelming. You need to consider many factors, including size, material, and load capacity. A ladder tray must support your specific wiring or cable needs effectively.

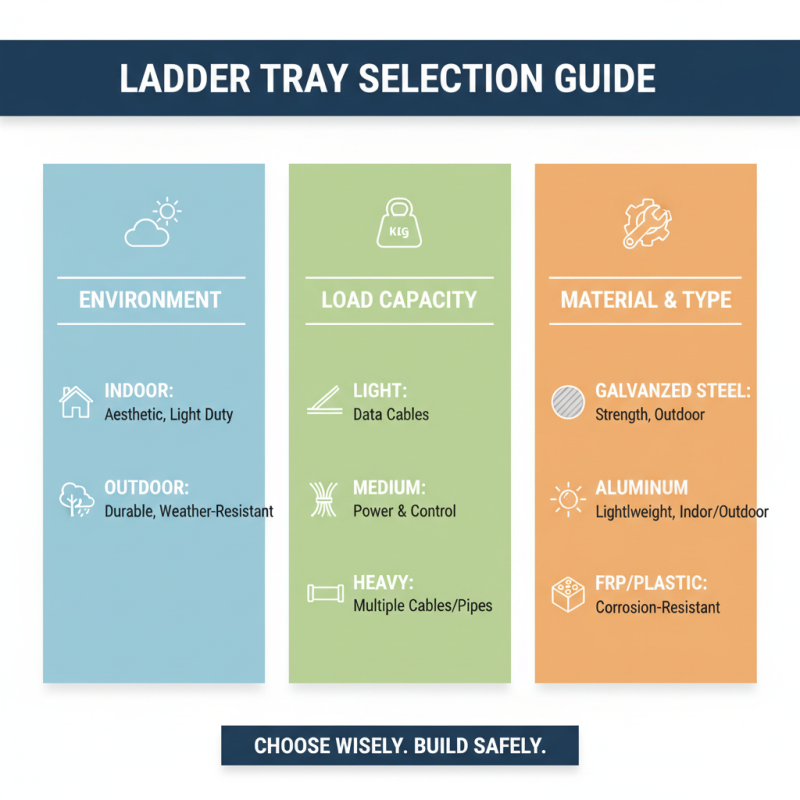

Materials are crucial in this choice. Aluminum, steel, and fiberglass each have unique strengths. Aluminum is lightweight yet strong, while steel offers durability. Fiberglass is resistant to corrosion, which could be important in certain environments. Balancing these factors can feel daunting.

When evaluating your project needs, think beyond just the technical aspects. Reflect on how your choice impacts installation and future maintenance. Every selection in the process matters. This will help you make a clearer decision when you shop for the ideal ladder tray.

Factors to Consider When Selecting a Ladder Tray

Choosing the right ladder tray for your project can be a daunting task. Several factors must be weighed carefully. Consider the environment where the tray will be installed. Is it an indoor or outdoor setting? Outdoor conditions may require more durable, weather-resistant materials. Indoor projects might prioritize aesthetic appeal.

The load capacity is another critical aspect. Ensure the ladder tray can support the weight of cables and other components. Overloading a tray can lead to failures and safety hazards. Assess the expected load and select accordingly.

Tips: Always double-check weight limits. Remember, safety first!

Size matters too. Measure the installation area precisely. A tray that's too wide or too narrow can create installation issues. Think about future growth as well. It’s wise to choose a size that accommodates potential expansions. Flexibility in design can save time later.

Tip: Don’t forget to think ahead! Planning can prevent frustrating adjustments in the future.

Keep in mind the accessibility for maintenance. Complex installations can become challenging to service later on. A design that provides easy access can save time and effort during upkeep. Reflect on these factors as you make your selection.

Types of Ladder Trays and Their Applications

Choosing the right ladder tray involves understanding the different types available. Ladder trays are versatile and serve various needs in projects.

Wire mesh trays are lightweight and easy to install. They allow for good airflow, making them perfect for run cables that generate heat.

On the other hand, perforated trays offer more support and safety. Their design helps to securely hold cables in place. This type is ideal for industrial settings where cable stability is vital.

Solid bottom trays provide maximum protection against dust and moisture. They can be heavier but are often necessary for outdoor installations.

When selecting, consider the environment. Will it be in a clean, controlled area or an unpredictable outdoor setting? Not all trays function well in all spaces. You'll find yourself reflecting if you chosen the right material. A mismatch could lead to issues later. Ensure the design meets your project needs without overcomplicating things.

Material Choices for Ladder Trays: Pros and Cons

Selecting the right material for a ladder tray is a crucial decision. There are several options available, each with its own advantages and drawbacks. Aluminum, for example, is lightweight and resistant to corrosion, making it a popular choice for many projects. According to industry reports, aluminum trays can reduce installation costs by up to 30% due to their ease of handling. However, they may not withstand very high temperatures.

Steel ladder trays are another option. They offer great strength and durability, often preferred in heavy-duty applications. However, they require additional coatings to prevent rust. A report from a leading construction firm indicates that over 40% of maintenance costs in industrial settings are related to rust on metal structures. This statistic emphasizes the need for careful material selection based on project demands.

FRP (Fiberglass Reinforced Plastic) trays are gaining attention. They are resistant to chemicals and do not corrode. However, some users report that they can be brittle under certain conditions. Balancing cost, strength, and environmental factors is necessary. Each project may need different solutions based on site conditions and specific requirements. It's important to analyze both immediate and long-term needs before making a final decision.

Sizing and Capacity Requirements for Ladder Trays

When selecting a ladder tray, understanding sizing and capacity is crucial. The size of the tray must match the cable load you intend to carry. A misunderstood capacity can lead to serious issues. It's beneficial to measure the cables and materials in advance. Consider their diameter and weight. This will help avoid future complications.

The width of the ladder tray influences cable management. A narrow tray might cause overcrowding, while an excessively wide one could waste space. Ensure to leave room for heat dissipation. Ventilation is important for preventing overheating. Ignoring this can result in unexpected failures.

Keep in mind the installation environment as well. Indoor and outdoor settings have different criteria. Outdoor trays should protect against weather elements. Rain or UV exposure can degrade materials over time. Regular checks can prevent significant damages. Reflecting on your choices will help refine future projects.

How to Choose the Right Ladder Tray for Your Project? - Sizing and Capacity Requirements for Ladder Trays

| Tray Type | Width (inches) | Height (inches) | Load Capacity (lbs) | Material |

|---|---|---|---|---|

| Standard Ladder Tray | 12 | 3 | 150 | Steel |

| Heavy-Duty Ladder Tray | 18 | 4 | 200 | Aluminum |

| Lightweight Ladder Tray | 10 | 2 | 75 | Plastic |

| Cable Ladder Tray | 14 | 3.5 | 120 | Galvanized Steel |

| Wire Mesh Ladder Tray | 16 | 3 | 100 | Stainless Steel |

Installation Best Practices for Ladder Trays in Projects

When installing ladder trays, attention to detail is crucial. Proper installation not only ensures safety but also maximizes efficiency. According to industry reports, about 30% of electrical failures can be traced back to inadequate support structures, including ladder trays. This means that choosing the right materials and adhering to best practices can prevent significant operational disruptions.

Start by evaluating the load capacity. The National Electrical Manufacturers Association (NEMA) recommends that ladder trays should support at least 50% more than the expected load. Ensuring proper spacing between supports is essential. Typically, a distance of 10 feet is recommended for most applications. However, this may require adjustment based on environmental factors and cable types. Tightening connections regularly is vital. Neglecting this can lead to slippage and misalignment over time, risking cable integrity.

Lastly, think about accessibility for maintenance. Ladder trays should be installed in a way that allows easy access to cables and connections. This consideration often gets overlooked in the planning phase. Ignoring it can lead to future complications and added costs. The importance of visibility and space for tools during maintenance cannot be underestimated. Reflecting on these practices helps in achieving a successful installation.

Related Posts

-

How to Choose the Right Cable Tray for Your Electrical Installation Needs

-

5 Essential Tips for Choosing the Right Wire Cable Tray for Your Project

-

How to Choose the Right Cable Tray for Your Electrical Wiring Needs

-

2025 Top Electrical Cable Tray Trends You Need to Know

-

Quality Driven Chinese Manufacturing in Global Leader Best Cable Management Tray

-

10 Essential Checklist Items for Sourcing the Perfect Basket Cable Tray for Your Project