10 Best Cable Ladders for Efficient Cable Management in 2023

In an increasingly connected world, effective cable management has become essential for both commercial and residential spaces. The demand for organized systems to handle the intricate web of cables is ever-growing, and one of the most efficient solutions on the market is the cable ladder. According to industry expert John Smith, a renowned specialist in cable management systems, "A well-designed cable ladder not only optimizes space but also enhances safety by preventing cable damage and potential hazards."

As we move into 2025, the need for top-quality cable ladders is more pronounced than ever, with advancements in design and materials leading to better functionality and durability. Our exploration of the "2025 Top 5" cable ladders highlights the best options available for achieving a clutter-free and efficient environment, ensuring that both professionals and DIY enthusiasts can find the right solutions for their specific needs. This guide will delve into the features, benefits, and unique aspects of these leading cable ladder systems, paving the way for an organized and efficient cable management strategy.

Top Features to Look for in Cable Ladders for Effective Management

When choosing the best cable ladders for effective cable management, several key features should be prioritized to ensure efficiency and safety. First, consider the material of the cable ladder. Durable materials such as steel or aluminum provide structural integrity and can withstand varying environmental conditions. Additionally, lightweight designs facilitate easier installation, making them suitable for a wide range of applications.

Another crucial feature is the ladder's load capacity. Selecting a cable ladder that can accommodate the weight of your cables is essential to prevent sagging and ensure longevity. Look for ladders with adjustable rungs or supports, which offer versatility in cable distribution and space utilization.

Tips: When organizing your cables within the ladder, utilize cable ties or Velcro straps to keep them neatly in place. This not only enhances aesthetics but also prevents tangling. Regularly inspect your cable management system for wear and tear, ensuring a safe and organized setup. Finally, consider adopting color coding for cables to facilitate easy identification during maintenance or troubleshooting.

Comparing Different Materials Used in Cable Ladder Construction

When selecting the best cable ladders for efficient cable management in 2023, understanding the materials used in their construction is crucial. Typically, cable ladders are made from aluminum, steel, or fiberglass.

Aluminum is lightweight, corrosion-resistant, and ideal for applications where mobility is essential. Steel, while heavier, offers superior strength and durability, making it suitable for heavy-duty installations. Fiberglass, on the other hand, is non-conductive and resistant to various chemicals, making it an excellent choice for environments with electrical hazards.

Tips for choosing the right material include assessing the environment where the ladder will be used. For outdoor applications, consider materials that withstand harsh weather conditions. If your installation requires a strong resistance to chemicals, fiberglass could be your best bet. Additionally, always evaluate the weight capacity needed for your specific cable load to ensure safety and efficiency.

Another factor to consider is the ladder's design features, such as rung spacing and width. These aspects can significantly affect cable organization and maintenance. Keep in mind that while aluminum ladders can be easier to install due to their lightweight nature, steel options may provide better long-term stability for extensive systems. Choosing the right material not only enhances performance but also optimizes the infrastructure in place for cable management.

Step-by-Step Guide to Installing Cable Ladders for Maximum Efficiency

When it comes to effective cable management, installing cable ladders is crucial for organizing and securing cables in various environments. A study published by the International Society of Automation shows that improper cable management can increase maintenance costs by up to 30%. Therefore, understanding the installation process is key to enhancing efficiency and reducing overheads.

To begin, choose a suitable location for your cable ladder, keeping in mind the weight limits and environmental factors such as humidity and temperature. Securely mount the ladder using brackets, ensuring that they are evenly spaced. Industry standards recommend spacing brackets no more than 10 feet apart for optimal support. After installation, carefully run your cables through the ladder, keeping them grouped and labeled for easy identification.

Tips: Always use cable ties or Velcro straps to bundle cables together, minimizing the chance of tangling or damage. Additionally, when planning your cable paths, ensure that they avoid any sharp edges, as this can lead to cable wear over time. Finally, regularly inspect your cable ladders and connections to maintain an organized and efficient setup.

Maintenance Tips for Prolonging the Life of Your Cable Ladders

To ensure the longevity of your cable ladders, regular maintenance is essential. Begin by performing routine inspections to check for any signs of wear and tear, such as corrosion or bent rungs. Promptly addressing these issues can prevent further damage and prolong the lifespan of your ladder. Additionally, make a habit of cleaning your cable ladders regularly. Dust, dirt, and debris can accumulate and lead to deterioration over time. Using a mild detergent and soft cloth can help maintain their condition and functionality.

Furthermore, be mindful of how you use your cable ladders. Avoid overloading them beyond the recommended weight capacity, which can cause structural stress and lead to premature failure. Proper storage is also crucial; ensure that they are not exposed to harsh weather conditions when not in use. By following these maintenance tips, you can significantly enhance the durability and efficiency of your cable ladders, ensuring they remain an effective solution for your cable management needs throughout the years.

10 Best Cable Ladders for Efficient Cable Management in 2023 - Maintenance Tips for Prolonging the Life of Your Cable Ladders

| Cable Ladder Type | Material | Load Capacity (kg) | Length (m) | Weight (kg) | Maintenance Tips |

|---|---|---|---|---|---|

| Standard Ladder | Steel | 1000 | 3 | 15 | Regular cleaning and inspection |

| Heavy-Duty Ladder | Aluminum | 1500 | 4 | 20 | Avoid excessive bending and load |

| Cable Tray Ladder | PVC | 500 | 2.5 | 10 | Check for cracks and wear |

| Vented Ladder | Galvanized Steel | 800 | 3.5 | 18 | Keep free from debris |

| Fixed Ladder | Stainless Steel | 1200 | 2 | 14 | Inspect for corrosion |

Best Practices for Organizing Cables Using Ladders in Various Settings

Proper cable organization is essential in maintaining both efficiency and safety in various work environments. According to a report by the National Fire Protection Association (NFPA), poorly managed cables are a common cause of workplace hazards, leading to increased risks of trips, falls, and electrical fires. Utilizing cable ladders offers a structured way to keep cables organized, reducing clutter and creating clear pathways that enhance safety. In a study by the Occupational Safety and Health Administration (OSHA), it was found that proper cable management can lead to a 30% decrease in workplace incidents related to cable tangling and related hazards.

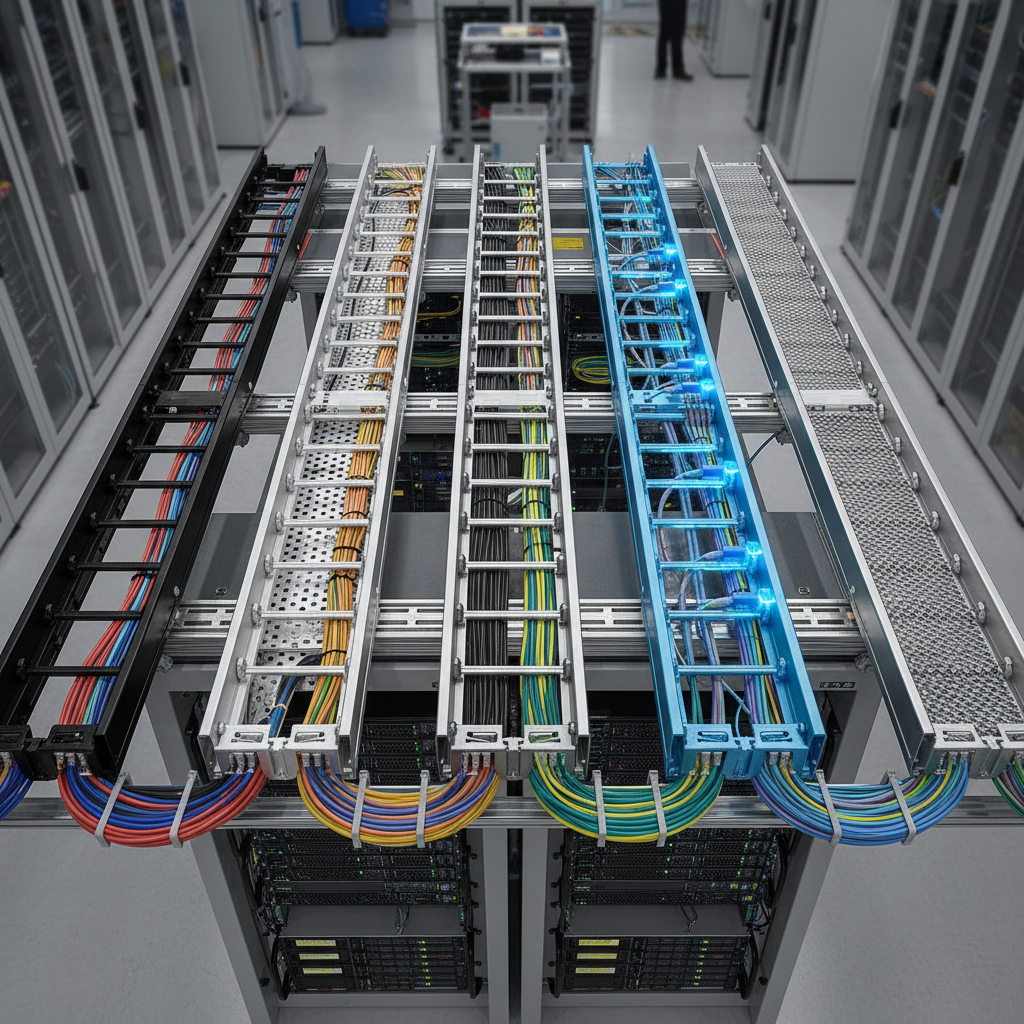

In different settings, such as offices, data centers, and industrial environments, the methodology for organizing cables using ladders can vary. For instance, in data centers, vertical and horizontal cable ladders are vital in keeping a large volume of cables neat and accessible, facilitating easier maintenance and upgrades. A survey by the International Data Corporation (IDC) revealed that companies that implement systematic cable management practices see a 25% increase in operational efficiency, illustrating the importance of using cable ladders not just for tidiness but also for enhancing technical workflows. In office settings, using adjustable cable ladders allows for flexibility, catering to different configurations and ensuring that cables do not impede daily operations.

10 Best Cable Ladders for Efficient Cable Management in 2023

This chart represents the cable capacity (in kg) of ten different cable ladders available in 2023, highlighting their efficiency in cable management.

Related Posts

-

Solutions for Optimal Cable Management with Best Cable Basket

-

How to Choose the Best Wire Cable Tray for Your Industrial Needs

-

Exploring Alternative Solutions to the Best Wire Basket Cable Tray

-

Discover Premium Cable Racks from China's Leading Manufacturing Hub

-

How to Choose the Right Cable Tray for Your Electrical Installation Needs

-

Exploring Innovative Alternatives to the Best Cable Rack Solutions for Efficient Organization