Top 10 Benefits of Using Aluminum Cable Trays for Electrical Installations

In the realm of electrical installations, the choice of materials can significantly influence the efficiency and safety of the entire system. As experts emphasize the importance of innovative solutions in modern infrastructure, John Smith, a leading specialist in cable management systems, notes, “The use of aluminum cable trays not only enhances organization and accessibility, but it also supports a sustainable engineering approach.” Aluminum cable trays have emerged as a popular solution for countless applications due to their numerous advantages over traditional cable management systems.

The benefits of using aluminum cable trays are vast and multifaceted. They provide excellent durability, resistance to corrosion, and lightweight properties, making them an ideal choice for both indoor and outdoor environments. Moreover, their ability to optimize airflow around cables encourages better heat dissipation, ultimately prolonging the lifespan of electrical systems. In an age where efficient and adaptable solutions are paramount, understanding the top benefits of aluminum cable trays can lead to more informed decisions, enhancing both safety and performance in electrical installations.

Benefits of Lightweight Aluminum in Cable Tray Designs

Aluminum cable trays are increasingly favored in electrical installations due to their lightweight nature, which directly impacts their installation and maintenance processes. Unlike heavier materials, aluminum trays are easier to maneuver and install, reducing the physical strain on workers and minimizing the time required for setup. This lightweight characteristic not only streamlines the installation but also enhances the overall efficiency of projects, allowing larger installations to be completed with fewer resources.

Moreover, the lightweight properties of aluminum contribute to a reduction in support structures needed for cable management systems. When using traditional materials, additional supports may be necessary to bear the weight, increasing both material costs and labor. With aluminum, the same level of structural integrity can be achieved, leading to significant cost savings. Additionally, aluminum’s corrosion resistance further enhances its longevity, ensuring that the cable trays remain functional and reliable over time, ultimately reflecting a wise investment for electrical installations.

Top 10 Benefits of Using Aluminum Cable Trays for Electrical Installations

Enhanced Durability and Resistance of Aluminum Cable Trays

Aluminum cable trays are becoming the preferred choice for electrical installations due to their enhanced durability and resistance compared to alternative materials. One of the key advantages of aluminum is its remarkable strength-to-weight ratio, which allows for robust support of electrical cabling without adding excessive weight to the structure. This characteristic is essential in environments where minimizing load on ceilings and walls is a priority. Moreover, aluminum's inherent resistance to corrosion makes it an ideal material for installations in humid or chemical-laden environments, ensuring a longer lifespan and reduced maintenance costs.

In addition to their resistance to corrosion, aluminum cable trays can withstand extreme weather conditions, making them suitable for both indoor and outdoor applications. Unlike steel trays that can rust and degrade over time, aluminum maintains its integrity, even in harsh climates. This durability translates into enhanced safety for electrical systems, as it reduces the risk of failure or damage due to environmental factors. Furthermore, aluminum is non-magnetic and non-combustible, adding further layers of safety in sensitive electrical installations. The combination of these properties not only ensures longevity but also instills confidence in users regarding the reliability and performance of their electrical infrastructure.

Top 10 Benefits of Using Aluminum Cable Trays for Electrical Installations

| Benefit | Description | Durability Rating | Resistance Type |

|---|---|---|---|

| Lightweight | Aluminum is lighter than steel, making installation easier and reducing structural load. | High | Corrosion Resistance |

| Corrosion Resistance | Aluminum is naturally resistant to corrosion, extending the lifespan of installations. | High | Oxidation |

| Low Maintenance | Requires less maintenance over time compared to other materials. | Medium | Rust |

| Aesthetically Pleasing | Aluminum can be finished in various colors, enhancing aesthetics in installations. | High | Visual Appeal |

| Electrical Conductivity | Excellent conductor of electricity, ensuring efficient power distribution. | High | Electrical |

| Recyclability | Aluminum is 100% recyclable, promoting sustainability in electrical installations. | High | Environmental |

| Thermal Conductivity | Good thermal conductivity helps in dissipating heat from cables effectively. | Medium | Heat |

| Non-Magnetic | Does not interfere with magnetic fields, making it suitable for sensitive areas. | High | Magnetic Interference |

| Versatility | Can be used in various applications, including industrial and commercial settings. | High | Application Flexibility |

Cost-Effectiveness of Aluminum for Long-Term Electrical Projects

When considering electrical installations, the choice of materials significantly affects both performance and cost. Aluminum cable trays have emerged as a preferred option due to their lightweight nature combined with impressive durability. This characteristic not only simplifies transportation and installation but also reduces labor costs associated with handling heavier materials. Over the lifespan of electrical projects, this initial cost savings can lead to substantial financial benefits, especially in large-scale installations where numerous trays are needed.

In the long term, aluminum’s resistance to corrosion and rust ensures that maintenance costs remain minimal, further amplifying its cost-effectiveness. Unlike other materials that may require regular inspections and replacements, aluminum retains its structural integrity, reducing the need for frequent upkeep. Additionally, its recyclability enhances its value, offering both environmental benefits and cost savings when trays reach the end of their useful life. Thus, choosing aluminum cable trays is not just a sensible financial decision, but also a commitment to sustainable practices in electrical installations.

Improved Aesthetics and Versatility in Installation Environments

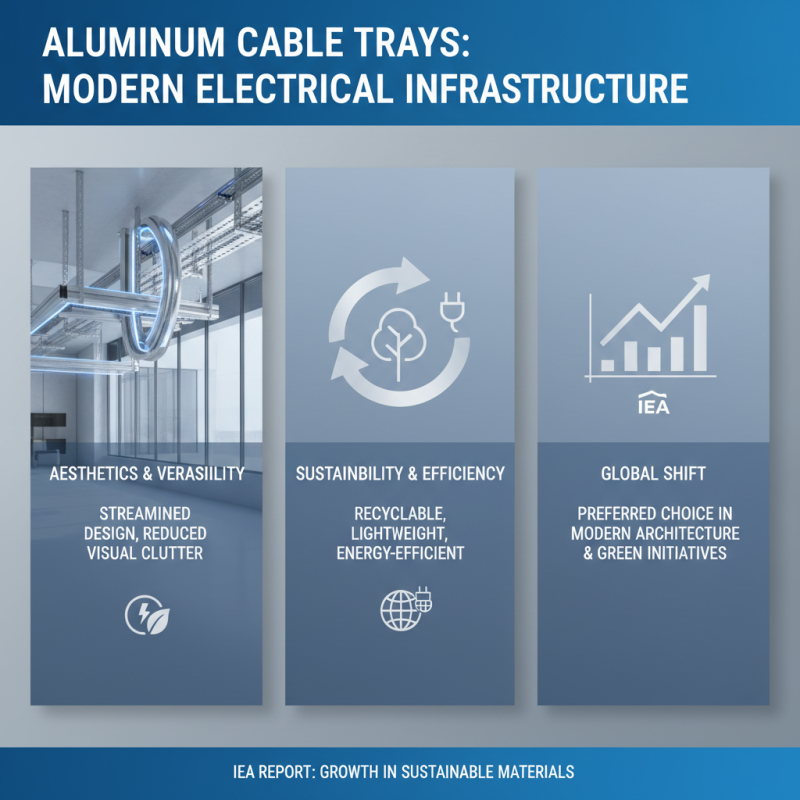

Aluminum cable trays have emerged as a preferred choice for electrical installations, primarily due to their improved aesthetics and versatility in various environments. With the growing emphasis on streamlined designs in modern architecture, aluminum cable trays blend seamlessly into any setting, reducing visual clutter and enhancing the overall appearance of utility spaces. According to a report by the International Energy Agency (IEA), the shift towards sustainable materials in infrastructure has made aluminum an even more attractive option, owing to its recyclable properties and lightweight nature.

Moreover, the versatility of aluminum cable trays in installation environments cannot be overstated. They can be customized easily to accommodate different layouts and complexities, making them suitable for both commercial and industrial applications. A study conducted by the National Electrical Manufacturers Association (NEMA) highlighted that installations using aluminum cable trays can reduce labor time by up to 30%, enabling faster project completion while maintaining a polished look. This adaptability allows for efficient management of electrical wiring while ensuring compliance with safety standards, resulting in an optimal blend of functionality and visual appeal.

Sustainability and Environmental Impact of Using Aluminum Cable Trays

The sustainability and environmental impact of using aluminum cable trays are significant considerations in modern electrical installations. Aluminum is a highly recyclable material, and the manufacturing processes involved in producing aluminum trays have become increasingly eco-friendly. By opting for aluminum, businesses can reduce their carbon footprint since the energy required for recycling aluminum is substantially lower than that needed for producing new aluminum from raw materials. This recycling capability not only conserves natural resources but also minimizes waste, making aluminum a smart choice for environmentally conscious projects.

Furthermore, aluminum cable trays are lightweight yet durable, leading to lower transportation emissions due to reduced fuel consumption. Their long lifespan contributes to sustainability, as fewer replacements are needed over time. When aluminum trays reach the end of their functional life, they can be easily recycled, thus completing a sustainable lifecycle. This effectively reduces the environmental burden associated with electrical installations while promoting a responsible approach to resource management in the industry. By integrating aluminum cable trays into their projects, companies demonstrate their commitment to sustainability and environmental stewardship.

Related Posts

-

Understanding Wire Basket Cable Trays: The Key to Efficient Cable Management in Modern Infrastructure

-

How to Choose the Right Cable Tray for Your Electrical Installation Needs

-

Unlocking Global Opportunities: China's Premium Threaded Rods for Reliable Partnerships

-

Exploring the Advantages of Metal Cable Trays: The Future of Electrical Infrastructure

-

How to Choose the Right Cable Tray for Your Electrical Wiring Needs

-

Exploring Innovative Alternatives to the Best Cable Rack Solutions for Efficient Organization