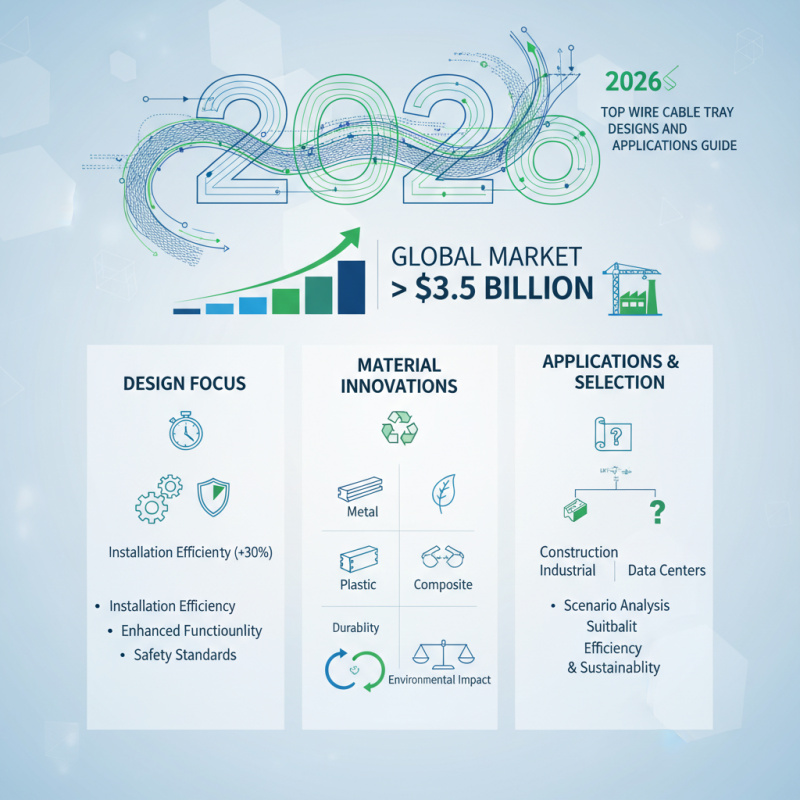

2026 Top Wire Cable Tray Designs and Applications Guide?

The wire cable tray industry is evolving rapidly, shaped by technological advancements and changing client needs. The global wire cable tray market is projected to surpass $3.5 billion by 2026. This growth is driven by the increasing demand for effective cable management solutions in construction and industrial environments. New designs focus on enhancing functionality while maintaining safety standards.

Recent reports indicate that installation efficiency can improve by over 30% when using well-designed wire cable trays. However, the variety of designs can overwhelm project managers. Not all designs suit every application, leading to potential misapplication. This highlights the need for comprehensive guides that not only showcase top designs but also analyze their suitability for specific scenarios.

In an era where sustainability is key, various materials are being explored for modern wire cable trays. Metal, plastic, and even composite materials are gaining attention. Yet, challenges arise in balancing durability with environmental impact. Ultimately, users must consider these factors when selecting wire cable trays to maximize both efficiency and sustainability.

Top Trends in Wire Cable Tray Design for 2026

As we look ahead to 2026, the wire cable tray design landscape is set to evolve. Key trends emphasize sustainability and efficiency. More designs incorporate recycled materials, reducing environmental impact. Companies will prioritize modular systems for flexibility and adaptability. These designs allow for easy expansion, catering to diverse project needs.

Another significant trend is the focus on aesthetics. Wire cable trays are moving beyond functionality. Sleek designs with customizable colors and finishes will catch the eye. This shift highlights an understanding of the workspace environment. An appealing appearance can enhance productivity and morale.

However, challenges remain. Many designs struggle with balance between form and function. Sometimes, aesthetic choices may compromise load capacity or accessibility. Designers must carefully evaluate these trade-offs. Clear communication with stakeholders is essential for achieving optimal solutions. The journey to innovative designs is continuous and requires open-mindedness in the face of these dilemmas.

Key Materials Used in Modern Wire Cable Tray Manufacturing

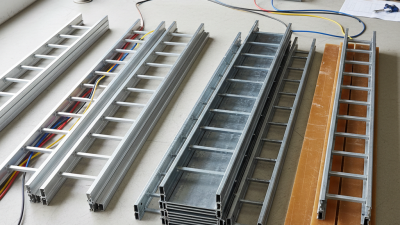

When it comes to wire cable trays, materials play a crucial role in their design and function. Commonly used materials include steel, aluminum, and fiberglass. Each material offers distinct benefits. For example, steel is known for its durability and strength. It can support heavy loads, making it suitable for industrial applications. However, it is also susceptible to rust if not properly coated.

Aluminum, on the other hand, is lighter and resistant to corrosion. This material is ideal for environments requiring mobility and flexibility. Its aesthetic appeal makes aluminum a choice for areas where visibility is essential. Yet, its lightweight nature can limit load-bearing capacity in some cases.

Fiberglass is another important option. It resists chemicals and moisture, making it perfect for harsh environments. Still, it may not support as much weight as metal options. Each material presents pros and cons. Selecting the right one demands careful consideration of the specific use case. Will you prioritize strength or flexibility? What environment will the tray face? These questions are vital in identifying the most suitable material for your wire cable tray design.

2026 Top Wire Cable Tray Designs and Applications

Common Applications of Wire Cable Trays Across Various Industries

Wire cable trays serve a vital role in numerous industries. They help organize and protect electrical cables. In commercial buildings, these trays are often installed in ceilings and walls. They allow for easy access and maintenance of wiring systems. It is a practical solution for data centers, where cables can be extensive and complex. Using trays, technicians find it easier to manage large volumes of wiring.

In manufacturing, wire cable trays can streamline operations. They provide a way to route cables safely without cluttering the workspace. This organization reduces potential hazards and supports efficient workflows. Facilities often face challenges with temperature and moisture. Wire trays improve airflow, which helps in maintaining the integrity of cables. However, some designs may not withstand heavy industrial environments. Regular inspections are needed to ensure safety and functionality.

The healthcare industry also relies on wire cable trays. They support medical equipment installations, ensuring that cables are well-organized. This is crucial in hospitals, where every detail counts. A clear pathway can help speed up maintenance or equipment upgrades. Yet, it's important to consider the layout carefully; poor installation can lead to accessibility issues. A balance between aesthetics and functionality is essential in every application.

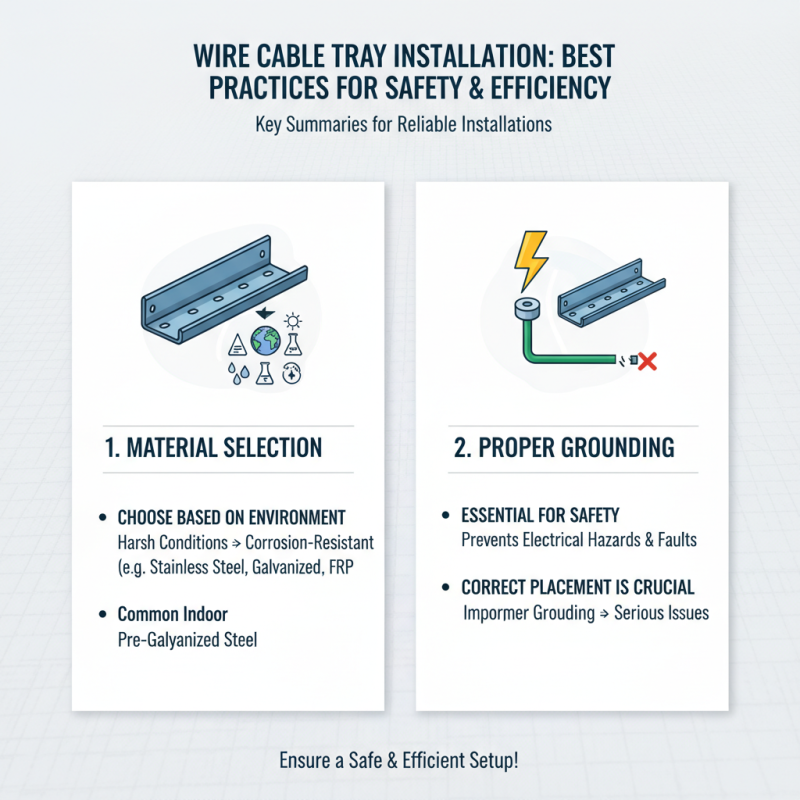

Installation Best Practices for Wire Cable Trays in 2026

Installing wire cable trays effectively involves several best practices to ensure safety and efficiency. It is crucial to choose the right materials based on the environment. For instance, harsh conditions may require corrosion-resistant options. Proper grounding must be performed to avoid electrical hazards. Any misplaced grounding can create serious issues down the line.

Placement is another vital factor. Cable trays should support the weight of cables without sagging. Incorrect support spacing can lead to structural failures. Securely fasten trays at recommended intervals to prevent movement. Regular inspections can help identify weaknesses early.

During installation, attention to layout is important. Plan the routing to minimize bends and loops. This not only improves aesthetics but also enhances functionality. Remember, it’s easy to overlook small details that can lead to larger complications later. Strive for a balance between practicality and organization in your design. Each installation should reflect a commitment to both performance and safety.

Future Innovations in Wire Cable Tray Technology and Design

The future of wire cable tray technology is exciting. Innovations are shaping designs to be more efficient and user-friendly. Manufacturers focus on lightweight materials that withstand heavy loads. These trays will be easier to install and maintain. Modern cable trays feature improved ventilation designs. This reduces heat buildup and prolongs the lifespan of cables.

Tips: When selecting wire cable trays, consider materials carefully. Not all materials are suitable for every environment. For instance, metal trays can rust in humid conditions. Additionally, keep an eye on load capacities. Overloading can lead to failures.

Further innovations include modular designs. These allow flexible configurations to fit diverse spaces. Customization is becoming a priority for many users. However, not all companies can offer this. It’s essential to ask questions and clarify needs. A poorly chosen cable tray can cause delays. Think about future expansions while planning. Balancing current needs and future growth is crucial.

2026 Top Wire Cable Tray Designs and Applications Guide

| Design Type | Material | Load Capacity (lbs) | Application | Innovative Features |

|---|---|---|---|---|

| Solid Bottom Tray | Steel | 1500 | Industrial Wiring | Corrosion resistant coating |

| Ladder Tray | Aluminum | 1200 | Data Centers | Lightweight and easy to install |

| Channel Tray | Hot-Dip Galvanized Steel | 2000 | Outdoor Applications | Durable against weather elements |

| Wire Mesh Tray | Stainless Steel | 1000 | Electrical Cabling | High ventilation and aesthetic appeal |

| Fiber Optic Tray | Plastic | 800 | Telecommunication | Protection against physical damage |

Related Posts

-

How to Choose the Right Cable Tray for Your Electrical Installation Needs

-

5 Essential Tips for Choosing the Right Wire Cable Tray for Your Project

-

Transform Your Space: The Ultimate Guide to Using Cable Hangers for a Clutter-Free Home

-

How to Choose the Right Cable Tray for Your Electrical Wiring Needs

-

2025 Top Electrical Cable Tray Trends You Need to Know

-

How to Choose the Right Ladder Tray for Your Project?