2025 Global Market Insights: Transforming Spaces with the Best Plastic Cable Tray Solutions

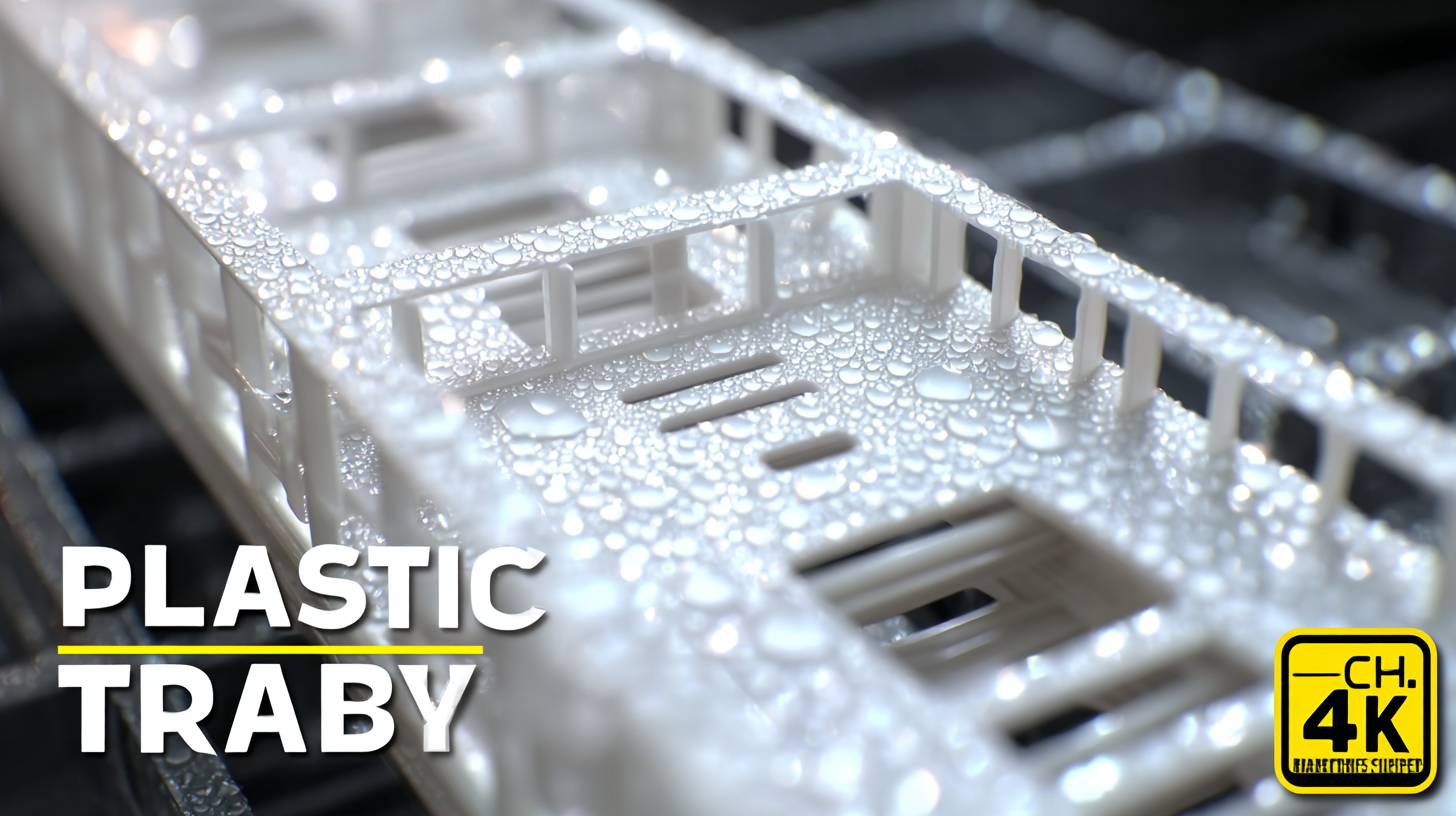

The rapid evolution of modern infrastructure demands innovative solutions that enhance efficiency and safety in electrical installations. Among these, plastic cable trays have emerged as a favored choice owing to their lightweight nature, corrosion resistance, and cost-effectiveness. According to a recent market report by Research and Markets, the plastic cable tray market is expected to witness significant growth, projected to reach USD 1.2 billion by 2025, with a CAGR of 5.8%. This growth is driven by their application in various sectors, including commercial, industrial, and residential construction, where managing cable organization is crucial. In this blog, we will delve into the detailed technical specifications of the leading plastic cable tray solutions available today, offering a comprehensive tutorial on selecting and implementing the best options to transform your spaces efficiently.

Understanding the Growing Demand for Plastic Cable Trays in 2025 Global Markets

As we approach 2025, the demand for plastic cable trays is projected to witness remarkable growth across global markets. According to a report by MarketsandMarkets, the plastic cable tray market is expected to expand at a CAGR of 5.4%, reaching a valuation of approximately $1.2 billion by 2025. This growth is primarily fueled by the rising need for safe and efficient cable management solutions in various sectors, including construction, telecommunications, and energy.

The increasing focus on sustainability and lightweight materials is significant in driving the transition to plastic cable trays. Unlike their traditional metal counterparts, plastic trays offer advantages such as corrosion resistance, lower weight, and reduced installation costs. Additionally, the shift towards greener technologies and materials in construction is influencing manufacturers to innovate, leading to enhanced designs that cater to specific industry needs.

As more companies strive for sustainability and cost-effectiveness, the adoption of plastic cable trays is set to accelerate, aligning with broader trends in global markets as we look towards 2025.

Key Factors to Consider When Selecting High-Quality Cable Tray Manufacturers

When selecting high-quality cable tray manufacturers, there are several key factors to consider that can significantly impact the efficiency and safety of your electrical installations. According to a recent report by MarketsandMarkets, the global cable tray market is projected to reach $6.3 billion by 2025, highlighting an increasing demand for durable and reliable cable management solutions. Companies must prioritize manufacturers that comply with international standards such as IEC and UL certifications, ensuring that their products meet stringent safety requirements.

Another critical factor is the material quality of the cable trays. Manufacturers offering trays made from high-quality materials like galvanized steel or aluminum are preferred for their corrosion resistance and longevity. A study by Allied Market Research indicates that metal cable trays hold approximately 62% of the market share in terms of revenue, reflecting their popularity in industrial applications. Furthermore, evaluating the manufacturer’s production capabilities and customization options can ensure that the trays meet specific project needs, contributing to better project delivery and operational efficiency.

Key Factors in Selecting High-Quality Cable Tray Manufacturers

This chart represents the key factors influencing the selection of plastic cable trays based on their ratings. Material quality and load capacity are rated highest, followed closely by corrosion resistance. Ease of installation and cost efficiency are important but have lower ratings.

Evaluating Material Quality: The Role of PVC and Steel in Cable Tray Durability

In the rapidly evolving landscape of industrial infrastructure, material quality plays a crucial role in the versatility and longevity of cable tray systems. Among the top contenders in this realm are PVC and steel, each offering unique benefits that cater to distinct project requirements. PVC cable trays, for instance, are celebrated for their lightweight nature and resistance to corrosion, making them an ideal choice for environments prone to chemical exposure. Their ease of installation and lower cost further contribute to their popularity in various applications.

On the other hand, steel cable trays provide unparalleled strength and durability, proving essential for heavy-duty installations. They are capable of withstanding substantial loads and harsh conditions, offering a long-term solution for industries such as manufacturing and energy. When evaluating cable tray solutions, project managers must consider the specific demands of their environment, as the right material selection not only enhances structural integrity but also contributes to the overall efficiency of the electrical management system. Ultimately, a deeper understanding of how PVC and steel function within cable tray systems empowers stakeholders to make informed decisions in their projects.

2025 Global Market Insights: Transforming Spaces with the Best Plastic Cable Tray Solutions

| Material Type | Durability Rating (Years) | Load Capacity (kg) | Corrosion Resistance | Cost per Meter ($) |

|---|---|---|---|---|

| PVC | 20 | 50 | Excellent | 2.5 |

| Steel | 25 | 100 | Good | 5.0 |

| Galvanized Steel | 30 | 120 | Very Good | 6.5 |

| Aluminum | 20 | 70 | Excellent | 7.0 |

Cost-Benefit Analysis: Investing in Reliable Plastic Cable Tray Solutions

Investing in reliable plastic cable tray solutions is increasingly becoming a game-changer for businesses looking to optimize their infrastructure. With 2025 in sight, organizations are conducting cost-benefit analyses to determine the long-term savings and efficiencies that these innovative products can provide.

Plastic cable trays offer advantages such as corrosion resistance, light weight, and ease of installation, which can significantly reduce labor costs and downtime.

When considering plastic cable trays, ensure to evaluate the total cost of ownership rather than just the initial purchase price. While they may have a slightly higher upfront cost compared to traditional materials, their longevity and low maintenance needs often lead to lower overall expenses. Furthermore, investing in quality supplies can enhance safety and compliance with industry standards, thereby protecting your investment over time.

Tips for implementing efficient cable tray solutions include planning your layout thoroughly to minimize material waste and ensure optimal cable management. It's also wise to keep future expansions in mind, allowing room for growth without necessitating a complete overhaul of the existing system. Lastly, always consult with industry experts to gain insights into the best practices and innovations that can further enhance your cable management strategies.

Industry Trends: Innovations in Cable Tray Design for Enhanced Space Management

As we move towards 2025, the cable management industry continues to evolve, offering innovative solutions that enhance space management while adapting to modern needs. The design of plastic cable trays has significantly transformed, allowing for streamlined installations that prioritize efficiency and aesthetic appeal. These advancements not only simplify the organization of electrical cables but also ensure safety and accessibility within various environments, from commercial spaces to industrial facilities.

**Tip:** When selecting plastic cable trays, consider the specific requirements of your installation area. Look for designs featuring integrated ventilation to prevent overheating, and assess their load capacity to ensure they meet the demands of your electrical systems.

The trend towards sustainability is shaping the future of cable tray design. Manufacturers are increasingly using recycled materials in their products, reducing environmental impact while maintaining high-performance standards. Additionally, innovative designs that facilitate easy modifications and expansions are gaining traction, allowing companies to adapt to changing space requirements with minimal disruption.

**Tip:** Always prioritize flexibility in your cable management solutions. Choose cable trays that can be easily adjusted or extended to accommodate future upgrades in technology and infrastructure, ensuring your space remains functional and organized for years to come.